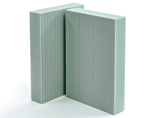

Armacell improves rPET foam offerings with ArmaPET Struct GRX

Structural foam core entirely made from recycled plastic bottles imparts efficiency gains, cost optimization and a more sustainable outlook for sandwich structure production.

Photo credit: Armacell

Armacell (Luxembourg), a global provider of flexible foam for the equipment insulation market and engineered foams, launches ArmaPET Struct GRX, a recycled PET (rPET) foam core technology that improves efficiency and sustainable sandwich structure production.

Entirely made from recycled plastic bottles, ArmaPET Struct GRX offers an optimized resin uptake process, further improving weight and cost. Its thermal and dimensional stability safeguards high-quality production, while high fatigue resistance ensures long-term performance and low lifetime maintenance. ArmaPET Struct GRX also boasts a more homogenous and finer cell structure compared to previous generations resulting in enhanced shear properties.

Extensive testing conducted by Armacell proves that ArmaPET Struct GRX exhibits comparable or even better mechanical performance to its predecessors — for example, its adjusted foam recipe delivers an increase of up to 30% in shear properties. It is available in a wide density range from 100-250 kg/m3.

Related Content

-

PUR composite sandwich panels for 3D automotive parts, high-volume panels and more

At its U.S. sites, Ascorium produces glass fiber/PUR 3D parts via semi-automated molding, high-volume flat panels via a continuous line while working toward bio-based PUR and recycling.

-

HyWaSand demonstrates large-series production potential for automotive TP sandwich components

Storage compartment flap for truck interior produced via fully automated continuous fiber thermoplastic sandwich molding technology shows suitability for series manufacture.

-

Airbus to design, build ESA ExoMars rover lander platform

The resurrected Rosalind Franklin composite rover mission’s key systems will be upgraded with support from the TAS, ESA and NASA for a planned launch in 2028.