Anisoprint launches 3D printer for continuous fibers

The Desktop Anisoprinting package comes with tailor-made plastic filament materials, verified printing profiles and a comprehensive training course.

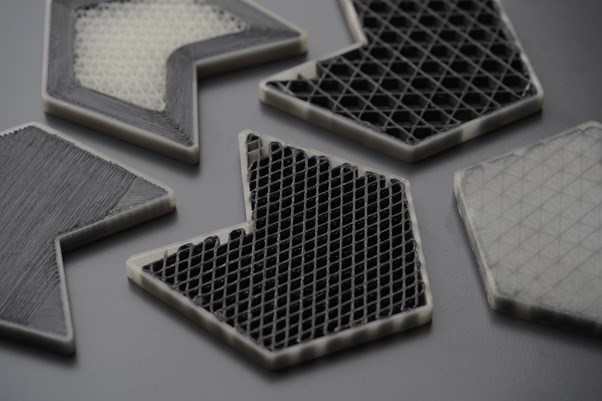

Photo Credit: Anisoprint

Anisoprint (Esch-sur-Alzette, Luxembourg) has launched a new additive manufacturing turnkey solution, Desktop Anisoprinting, that uses continuous fiber composites printing and reportedly enables manufacturers to produce highly optimized composite parts with minimal risk of failure. In addition to reinforcing materials and software, the Desktop Anisoprinting printing package includes new polymers, printing profiles and training.

Anisoprint says the system uses one of two plastic filament materials, CFC PA and the Smooth PA, that were developed for Desktop Anisoprinting by Polymaker (Shanghai, China). The CFC PA material is polyamide-based and designed for use with Anisoprint’s proprietary composite fiber coextrusion (CFC) technology. It offers low-viscosity melt flow that is said to promote good layer-to-layer binding. Smooth PA, also polyamide-based, is designed for printing external surfaces of a part. Its carbon fiber content is said to help prevent warping and provide a high-quality surface.

The printing package includes developed and verified printing profiles for a wide range of plastics. Profiles include settings for temperature, speed, layer thickness, cooling and other parameters.

Further, Desktop Anisoprinting comes with a “composites basics” online training course from Anisoprint experts with more than 10 years of experience in composite materials development. The includes topics such as continuous fiber 3D printing technologies overview, basics of composites and design, materials properties, hardware operation and more.

Related Content

-

Bucci Composites expands automotive production capabilities with facility addition, new high-ton presses

CW Top Shops recipient Bucci Composites shares an update on its facility expansion, automotive composites applications, sustainability, education initiatives and more.

-

Daher inaugurates Learning Center for training aeronautical talent

Daher offers a concrete solution to the shortage of qualified professionals in aerospace, providing a range of technical programs that prepare workers for the sector’s rigorous demands.

-

AMRC Training Centre introduces composites apprenticeship opportunity

With partners McLaren and Teledyne CML Composites, the Training Center will train new composites technicians in South Yorkshire to build up the future industry workforce.