Airtech launches recycled-grade Dahltram T-100GF resin

Thermoplastic polymer resin was designed to tackle distinctive industry challenges of large-scale 3D printing while also assisting with sustainability initiatives.

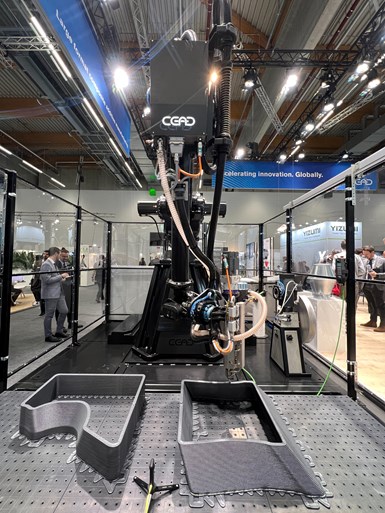

Live printing using the Dahltram T-100GF resin. Photo Credit: Airtech Advanced Materials Group

Dahltram T-100GF resin is Airtech Advanced Materials Group’s (Huntington Beach, Calif., U.S.) first recycled-grade thermoplastic polymer resin for pellet-fed, large-scale 3D printing. Developed with precision, the material was designed to tackle distinctive challenges of large-scale 3D printing while contributing to sustainability initiatives in the industry.

Dahltram T-100GF combines the power of recycled grade co-polyester resin with the strength of fiberglass reinforcement, resulting in a sustainable material that is suitable across diverse applications, including rapid prototyping, low-temperature molding, trimming tools, architectural structures, casting patterns and more. Airtech says it remains commited to expanding its product line with solutions that drive sustainability and contribute to a greener future through the use of large-scale additive manufacturing (AM) technologies.

Other benefits of Dahltram T-100GF resin beyond sustainability include the resin’s strength and durability. The inclusion of fiberglass reinforcement improves the material’s strength, promoting good durability and reliability across a spectrum of applications. The resin is also highly versatile, catering to a range of applications from rapid prototyping to architectural structures, offering an adaptable solution for manufacturers across various industries.

Dahltram T-100GF also provides an economically attractive alternative to traditional materials while still delivering performance. Airtech says this makes the resin an option for businesses aiming to streamline their production processes without compromising quality.

Related Content

-

Active core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

-

Composites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.