Products

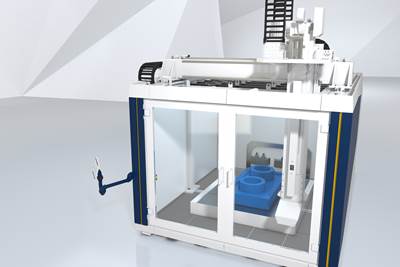

Isobaric double belt press is well suited to continuous production

CAMX 2023: Flexible and robust double belt presses from Held Technologie are adaptable to various base composite material requirements to produce top-quality, long-lasting products.

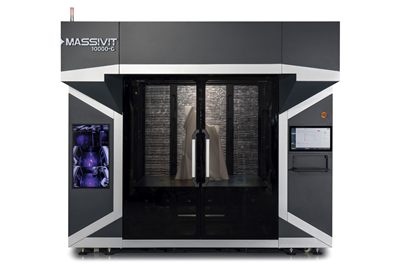

Read MoreLarge-scale additive system prints industrial molds for composites

CAMX 2023: The Massivit 10000-G, with gel dispensed printing offers an ultra-fast, sustainable and cost-effective way to digitize isotropic mold production for high-quality and more reliable composite parts.

Read MoreKraussMaffei launches large-scale 3D printer, print-on-demand services

PowerPrint, capable of using fiber-reinforced compounds, combines design freedom and cost efficiency for large-format printing applications. It is available for purchase or serviced through KraussMaffei.

Read MorePE adhesive creates strong, fast bonds to low surface energy substrates

IPS Adhesive’s Scigrip brand introduces SG400LSE, a transluscent, low-color adhesive that has proven its ability to bond to FRPS, metals, plastics and other polymers.

Read MoreHigh-efficiency, low-energy industrial ovens, furnaces and washers

CAMX 2023: International Thermal Systems (ITS) offers a range of equipment that maximizes manufacturing efficiencies and minimizes energy consumption that include OOA composite curing ovens.

Read MoreSpecialized cutting tool equipment accommodates automotive requirements

CAMX 2023: Hufschmied’s machining systems, particularly the company’s 194/195 T-Rex cutting tools and carbide cutting blades, are being presented for use on plastics, composites and other materials.

Read MoreFiberglass products target industrial application needs

CAMX 2023: Jrain FRP, with locations in China, Mexico and the U.S., is equipped with 16 years’ of experience engineering, designing and manufacturing fiberglass-reinforced industrial products.

Read MoreDAC mixer simplifies composites development, prototyping

CAMX 2023: The original German-made Hauschild SpeedMixer, enabling the homogenous mixing or grinding of composite materials is well-suited for laboratory work and small production quantities.

Read MoreCarbon fiber tooling addresses aerocomposites pain points

CAMX 2023: The result of extensive R&D, BlackBoard by Harcourt Industrial enhances efficiency, reduce costs and improve overall manufacturing performance compared to Invar tools.

Read MoreSpecialty additives for composites enable conductivity properties

CAMX 2023: Gallois SP2 Carbon is highlighting its specialty carbon fiber-based materials, graphite and reactive resins to achieve high-performance composite applications.

Read MoreAluula features recycle-ready composites in wind sports application

A patented fusion technology and proprietary X weave design enhance the light weight, strength and reliability of the Aeris and Aeris X materials, which make their first debut on Ocean Radio’s Glide AA-Series sports wing.

Read MoreSilicon carbide foam provides benefits in high-temperature, corrosive environments

CAMX 2023: ERG Aerospace’s Duocel silicon carbide foam has a working temperature of 3,600ºF, designed for hypersonic application and high-temperature, corrosive environments.

Read More