University of Sydney develops recycling method for composite waste

With 840,000 tonnes of composites waste looming on the horizon, Australian researchers have discovered a recycling approach with increased material recovery and improved energy efficiency.

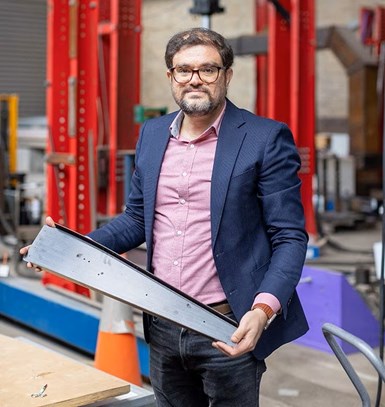

Dr. Ali Hadigheh holding waste material from an aircraft. Photo Credit, all images: Stefanie Zingsheim, University of Sydney

Researchers at the (Camperdown, Australia) have developed new methods to address future carbon and glass fiber composite waste from the automotive, aerospace and renewable industries.

“Carbon fiber composites are considered a ‘wonder’ material — they are durable, resistant to weathering and highly versatile — so much so that their use is projected to increase by at least 60% in the next decade alone,” says Dr. Hadigheh from the School of Civil Engineering. “But this growth also brings a huge increase in waste. For instance, it’s been estimated that around 500,000 tonnes of carbon and glass fiber composite waste from the renewable energy sector will exist by 2030.”

Wind turbine blades, hydrogen tanks, airplanes, yachts, construction and car manufacturing are a few examples that are anticipated to become key composite waste stream worldwide. The annual accumulation of carbon fiber-reinforced polymer (CFRP) waste from aircraft and wind turbine industries alone is projected to reach — the equivalent of 34 full stadiums — if suitable recycling methods are not adopted.

While recycling methods do exist, most of this waste currently goes to landfill or is incinerated. The production of “virgin” composites has further implications for the environment too, including resource depletion and high energy input during production.

This is despite the existence of numerous methods to recycle carbon fiber composites which a research team at the University of Sydney says, if fully implemented, have the potential to significantly reduce energy use by 70% and prevent key streams of materials from going to waste.

To tackle this issue, Dr. Hadigheh and his recent PhD graduate, Dr. Yaning Wei, have developed a new recycling method for composites. Published in , their approach reportedly ensures increased material recovery and improved energy efficiency compared to previous methods.

“Our kinetic analysis revealed that pretreated CFRP undergoes an additional reaction stage, enabling enhanced breakdown at lower temperatures compared to untreated CFRP,” says Dr. Hadigheh. “The solvolysis pretreatment not only facilitates greater breakdown but also preserves the mechanical properties of fibers by reducing heat consumption during recycling.”

Recycled fibers obtained from pretreated CFRP are said to have retained up to 90% of their original strength, surpassing the strength of fibers recovered through thermal degradation alone by 10%.

“To demonstrate the real-world applicability of our method, we successfully recycled part of a bicycle frame and airplane scraps made of CFRP composites using our hybrid approach. These results not only validate the effectiveness of chemical pretreatment but also demonstrate the improved mechanical characteristics of the recycled carbon fibers,” adds Dr. Hadigheh.

Recycled product.

In a previous , the team also presented a detailed evaluation of 10 different carbon and glass fiber composite waste treatment systems based on economic efficiency and environmental effects, taking into consideration the type of waste material and its geographical location.

Dr. Hadigheh’s team found that solvolysis — a method whereby materials can be broken down with an application of solvent under a specific pressure and temperature — could reclaim carbon fiber while delivering a high net profit. Thermal recycling methods such as catalytic pyrolysis and pyrolysis coupled with oxidation also provided a high economic return.

Solvolysis and electrochemical methods were also shown to lead to substantially lower CO2 emissions into the atmosphere than landfilling and incineration.

In conclusion, the university researchers say that manufacturers should look beyond continuously creating virgin material and, in parallel, develop recycled products from end-of-life streams.

“This is a huge opportunity,” says Dr. Wei. “And not only because various modes of recycling are cost-effective and minimally impactful on the environment. “In an era of mounting supply chain disruptions, local recycled products can provide a more immediate product when compared to imports and create a burgeoning advanced manufacturing industry.”

Dr. Hadigheh’s team is also developing methods for the recycling of composite materials and recently patented a machine to precisely align recycled carbon fibers, so that they can be repurposed.

The research papers were both funded by ARC DECRA DE200100406: Aligned recycled carbon fiber composites for high grade structural elements. Dr. Hadigheh works with a range of companies to develop to recycle composites waste.

Related Content

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreDevelopment of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

Read MoreRevisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

Read MoreRead Next

Anmet launches chipboard panels made from recycled composites

Starting from university R&D collaborations, the Polish recycling company has patented a shredding and manufacturing process for wood-replacement chipboards for use by the construction industry.

Read MoreKuusakoski announces plans for composite recycling plant in Finland

New composite shredding and treatment plant in southern Finland will enable the co-processing of composite waste for cement production.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More