Aluula, University of British Columbia develop recycling process for UHMWPE fiber composites

The researchers have developed high-strength molded panels made from recycled materials.

Advanced materials technology firm (Victoria, British Columbia, Canada) is collaborating with the University of British Columbia (UBC) to develop recycling applications for Aluula’s high-performance, ultra-high molecular weight polyethylene (UHMWPE) based composite materials.

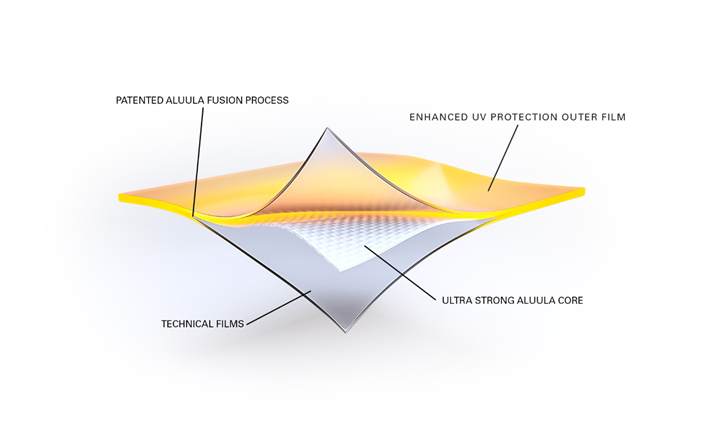

Using a patented fusion process, Aluula Composites has developed a way to fuse high-tech fibers and technical films together without the use of glues. This fusion process is said to create extremely light, strong and durable fabrics that are readily recylable.

An initial project with the Composites Research Network at UBC Vancouver established the ability to compress Aluula material off-cuts and end-of-life products into uniform, lightweight and ultra-durable panels.

According to Aluula, the recycling process keeps the UHMPWE fibers of the original materials intact, resulting in fiber-reinforced panels that are said to be 10x stronger than those molded from virgin UHMWPE.

Aluula is working with UBC Manufacturing Engineering (MANU) students, to develop and refine applications for these panels. Potential applications of these panels include backpack pack panels to low-friction wear plates, where strength, low weight, abrasion resistance and low friction are desirable.

“Working with UBC students on applications for these ultra-strong and ultra-durable products is proving to be invaluable as we refine our processes to ensure the recyclability of Aluula materials,” says Sam White, material scientist.

“Aluula has proven that sustainability and astounding performance can coexist without compromise. We look forward to leading the composite industry towards a more sustainable future,” says John Zimmerman, COO.

Related Content

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

ASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

-

Trends fueling the composites recycling movement

Various recycling methods are being considered for composites, from novel dismantling and processing, to building capacity and demonstrating secondary use applications.

.jpg;width=70;height=70;mode=crop)