Fraunhofer IPT achieves CFRTP tape recycling from H2 tanks

A novel recycling approach uses a peeling process to recover thermoplastic UD tapes from hydrogen pressure vessels, cites 90% of mechanical properties are maintained.

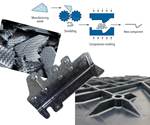

Recycled CFRTP UD tapes. Photo Credit: Fraunhofer IPT

Through the “Tankcycling” research project, (Fraunhofer IPT, Aachen, Germany) researchers have developed a novel recycling process to recover the fiber reinforcement of used hydrogen pressure tanks in a peeling process for reuse in new, lightweight products. The goal, to recycle fiber-reinforced polymers (FRP) without any significant loss of product quality, is reported to have succeeded, with more than 90% of the recycled material’s mechanical strength properties retained.

High-quality composite hydrogen tanks are typically manufactured in a laser-assisted tape winding (LATW) process. Glass or carbon fiber-reinforced thermoplastic (GFRTP/CFRTP) tape is wound over a base body made of plastic, the so-called liner. Fraunhofer IPT notes that the unidirectional (UD) tape that covers the pressure tank cannot be reused in the conventional life cycle of the pressure tank and ends up in hazardous waste dumps.

The recycling process patented by Fraunhofer IPT (DE 10 2016 117 559 A1) makes it possible to remove the UD tape from the liner in a peeling process. In this way, the tape can be reused for other products that are also manufactured with the tape winding process. Project researchers have developed a plant prototype with various modules: the tape passes through one in the recycling process before it is stored onto a spool at the end in another.

In downstream tests, the scientists checked the mechanical load-bearing capacity of the recycled material and the original material. Here, it was shown that the recycling process did not reduce the quality of the material significantly. Destructive standard tests demonstrated that the recycled material had lost only 5-10% of its mechanical quality compared with the virgin material. Based on these findings, researchers were able to define the requirements for the recycling process and develop a tank recycling module.

This module represents a further development of the recycling process, which was developed on a stationary test rig. In its miniaturized format, the tank recycling module can be attached to a robot arm. This innovation allows pressure tanks with their complex 3D geometry to be fully recycled, the researchers report. In addition, the recycling process and subsequent rewinding of the tape can be automated in this setup.

The recycling process with its implementation in the tank recycling module efficiently explores the limits of what is technically feasible while saving energy, material and costs. By recycling the FRP tapes, the process contributes to advancing the sustainable production of future thermoplastic fiber composite products that can be manufactured using the tape winding process.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Eaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

-

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.