Teijin aramid, carbon fibers used for museum façade panels

The new wing of the Stedelijk Museum Amsterdam is the first and largest composite building constructed from Teijin’s Twaron and Tenax fibers.

Source | Teijin

The Teijin Group (Tokyo, Japan) announced that its Twaron para-aramid fiber and Tenax carbon fiber were used to build 185 composite panels for the façade and canopy of a new wing of the Stedelijk Museum Amsterdam (Amsterdam, Netherlands). Measuring 100 meters by 25 meters, it is the world’s first and largest-scale composite building using Twaron and Tenax, Teijin says.

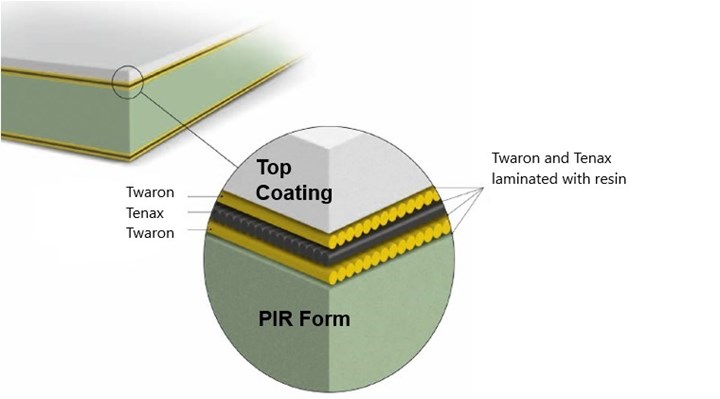

The new wing of the museum is known as the “bathtub” due to its distinctive shape. Twaron para-aramid fiber produced by Netherlands-based Teijin Aramid B.V. and Tenax carbon fiber produced by Teijin Carbon Europe GmbH in Germany were combined with vinyl ester resin in composite laminates, forming the outer skins of a composite sandwich construction with a core of PIR foam. Twaron and Tenax fibers are said to contract as temperature rises, unlike expanding resins, reportedly ensuring minimal thermal expansion of the panels while offering structural stability.

Source | Teijin

The Teijin Group has been sponsoring the Stedelijk Museum Amsterdam since 2007, as a cultural initiatives based on the company’s corporate philosophy to grow and evolve in harmony with society. Teijin is sponsoring the Colorful Japan exhibition, which opens Sept. 7, to emphasize the strong bonds between Japan, Teijin and the Netherlands.

Related Content

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

-

Airbus video highlights RACER compound helicopter first flight

Launched as part of a Clean Sky 2 program, a compound design — rotor, split fixed-wing, propulsive propellers — uses composites to cut fuel consumption and emissions by 20%.

-

Composites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

.jpg;width=70;height=70;mode=crop)