SGL Carbon to produce carbon fiber composite air taxi landing gear

SGL Carbon will begin serial production of its ultra-light composite landing gears in early 2021.

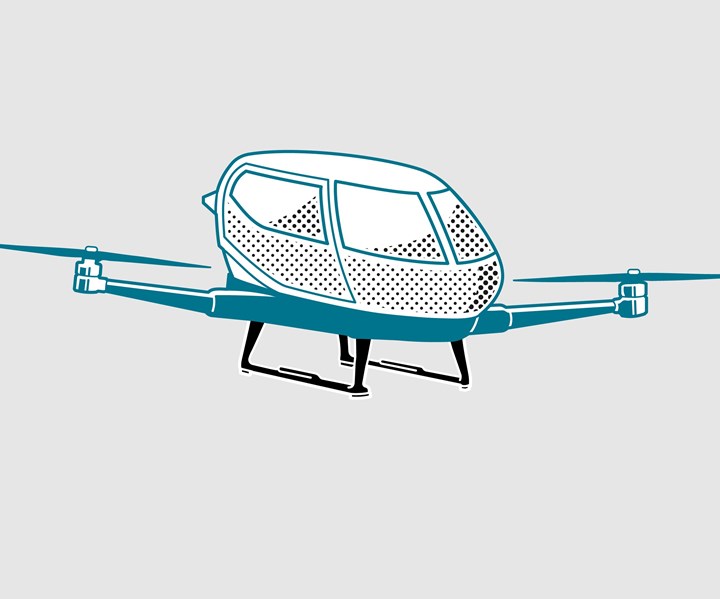

Design for air taxi landing skids developed with carbon fiber composites. Source | SGL Carbon

SGL Carbon (Weisbaden, Germany) reported on Jan. 20 that it will begin serial production of air taxi landing gear made from braided carbon fiber material early next year. The landing skids will be installed in around 500 air taxis worldwide over the next two years, the company says.

The 2-meter-wide by 1.5-meter-wide ultra-light landing skids will weigh less than 3 kilograms, making them about 15% lighter than a similar component made from aluminum. SGL Carbon says lightweighting is particularly important for increasing potential flight time capacity of the electric motor-powered air taxis.

The landing gear was developed in collaboration with customer experts and specialists from SGL Carbon. The carbon fibers for the component are produced at the SGL Carbon plant in Muir of Ord, Scotland. The final part is being manufactured at the SGL Carbon site in Innkreis, Austria.

“With with our landing gear, we help to shape this very new, promising application of manned, autonomous civil aviation. This involvement also demonstrates our wide range of services. From engineering, to prototype manufacture, to serial production with our own materials — all of our competences along the entire value chain made a contribution to the project,” says Dr. Andreas Erber, head of the aerospace segment of the Composites — Fibers & Materials business unit at SGL Carbon.

Related Content

-

Braided composites enable low-cost, high-rate fabrication

CAMX 2025: A&P Technology highlights its QISO and slit tape thermoplastic material capabilities through customer examples and industry applications.

-

Hexcel, A&P collaborate with NIAR to develop FAA certification framework for overbraided structures

Acceptable composite specifications, design data and methodology will enable affordable, high-rate structure manufacturing for DOD aircraft.

-

Composite Braiding awarded for TPC twin track cantilever support

Railway infrastructure cuts weight by 84%, carbon emissions by 80% and installation time by 50% while automated process offers ≥90% lower labor costs, waste and energy use versus traditional composites manufacturing.

.jpg;width=70;height=70;mode=crop)