Purdue University composites center opens large-scale additive lab, seeks consortium partners

Purdue’s Composites Manufacturing and Simulation Center (CMSC) cut the ribbon on the Thermwood LSAM Research Lab, which partners can access with Purdue’s ADDITIVE3D simulation module.

On Oct. 28, Purdue University’s (West Lafayette, Ind., U.S.) ) hosted a ribbon cutting event for its Thermwood LSAM Research Laboratory at Purdue University, and announced its Composites Additive Manufacturing & Simulation (CAMS) Consortium.

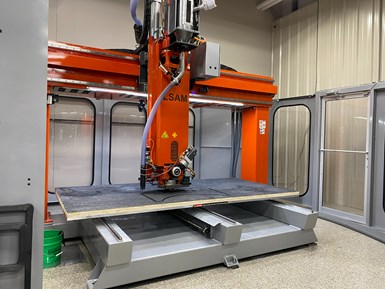

Located inside the CMSC at the Indiana Manufacturing Institute, the Thermwood LSAM Research Laboratory houses a LSAM 105 large-format, extrusion-based 3D printer and five-axis LSAM Additive Trimmer. According to Thermwood, the two-step system is capable of printing and trimming parts up to 5 x 10 x 4 feet at print rates up to 200 pounds per hour. The system has been modified to enable print temperatures over the typical 450°C, Thermwood says, for experimentation and research purposes.

R. Byron Pipes, executive director of the CMSC of Purdue University, said during the event that the initial focus for the laboratory will be composite tooling.

Ken Susnjara, chairman and CEO of Thermwood Corp. (Dale, Ind., U.S.), noted, “Our goal is to take this technology to new levels, and expand into mainstream markets.”

The CAMS Consortium aims to provide its paid members with access to Additive3D, a physics-based simulation workflow developed by Purdue in conjunction with Dassault Systèmes (Vélizy-Villacoublay, France) software; printing studies using the new laboratory’s LSAM 105 printer or CAMRI, a smaller-scale printer built by Purdue for R&D work; educational materials and training; and technical support from Purdue.

Five-axis LSAM trimmer at the Thermwood LSAM Research Laboratory. Photo Credit: CW

Eduardo Barocio, assistant director of additive manufacturing (AM) at the CMSC, explained during the event that Additive3D system is a simulation workflow that works in conjunction with Dassault software and extrusion deposition additive manufacturing (EDAM) to streamline and digitize the design and printing process for discontinuous fiber composites. Material and machine characteristics and properties are input into the software, and Dassault CATIA and SIMULIA are used to simulate part characteristics like geometry, stress and deformation; process parameters like heat transfer and temperature; and part performance.

Barocio noted that future iterations of Additive3D will expand to other AM processes and material types, including continuous fiber.

These announcements were part of Purdue’s Large-Scale Additive Manufacturing Celebration, which also celebrated the one-year anniversary of the opening of the 3DEXPERIENCE Lab and Education Center of Excellence with partner Dassault Systèmes. The celebration included speakers from Purdue University, Dassault Systèmes, Boeing and Thermwood, and focused on innovations in digital twins and simulation, and these partnerships aiming to propel the technology forward. Purdue’s research in these fields also goes beyond 3D printing. Speakers and researchers at the event spoke about additional digital twin and simulation projects such as Form3D, a project in partnership with Boeing for simulation-based carbon fiber/thermoplastic composite sheet forming, as well as multi-scale modeling of resin transfer molding (RTM), infusion and other processes.

Related Content

Optimized rib-reinforced hollow composites via printed molds

Addyx topology optimization and water-soluble mandrel enables simultaneous rib and skin layup for one-shot, high-strength, lightweight structures.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreAl Seer Marine, Abu Dhabi Maritime unveil world’s largest 3D-printed boat

Holding the new Guinness World Record at 11.98 meters, the 3D-printed composite water taxi used a CEAD Flexbot to print two hulls in less than 12 days.

Read MoreEaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

Read MoreRead Next

Purdue University to establish Thermwood LSAM research laboratory

Industry-funded research to pursue large-scale composite thermoplastic additive manufacturing, with the goal of providing services to enhance, encourage and expand the adoption of large-scale AM for diverse industrial applications.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More.jpg;width=70;height=70;mode=crop)