NCC, Network Rail join to construct composite footbridge

The U.K.’s National Composites Centre (NCC) and National Rail are teaming up to develop a composite footbridge with reduced cost and greenhouse gas emissions.

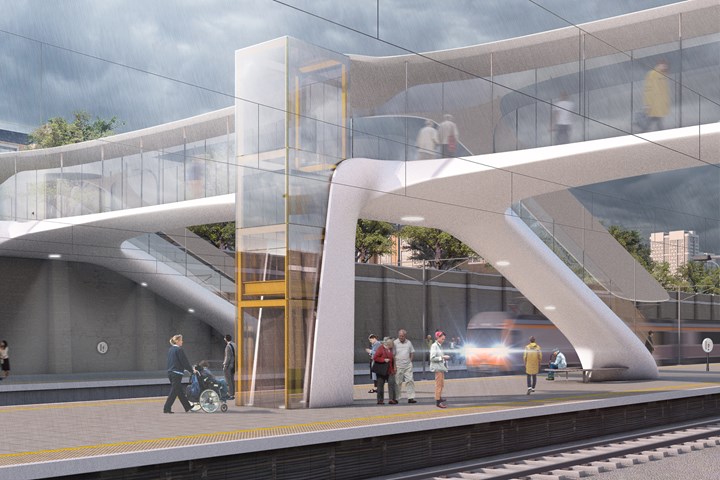

Photo Credit: National Composites Centre

The (NCC; Bristol, U.K.) reported on Sept. 15 that it has partnered with Tier 1 member (London, U.K.) to develop and build a composite footbridge. Further, the partnership will give Network Rail access to NCC’s composites research and development facilities.

The NCC and Network Rail plan to develop the “Futura” concept footbridge from (London, U.K.) and (Lyngby, Denmark). The companies hope to demonstrate the benefits of using composites in railway station environments for both new build and replacement structures.

“There is clear alignment between NCC and Network Rail’s long-term strategic goals — namely to accelerate the adoption of composites in construction and to support the UK’s supply chain development to achieve the Government’s Construction 2025 strategy,” says Richard Oldfield, chief executive of the NCC.

“Composites offer huge benefits to construction in their ability to be built using modern methods as well as the cost-effective nature of their construction and installation. They are a more sustainable solution, which will contribute to net-zero targets across the industry, and are an intrinsically safer and more aesthetically-pleasing option.”

According to the companies, the footbridge demonstrator will adopt a standardized design and a set of adaptable components created in factories with digital controls for simple, rapid, precision-fit assembly at the work site. The footbridge will also enable innovation that can be transferred to the wider transport infrastructure and improve the supply chain by targeting reduced cost and reduced greenhouse gas emission in line with .

“High-strength modern composite materials present huge opportunities for a new generation of bridges and structures,” comments Ian Firth, engineering designer with COWI. “I am particularly excited about the opportunity to optimize the design’s use on this project to achieve the best performance advantages that the material allows.”

Related Content

-

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

Corebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.