Markforged launches first FR continuous fiber-reinforced plastic for 3D printing

V-0 rated Onyx FR to open new applications in aerospace, defense and automotive

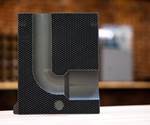

Markforged (Cambridge, Mass., U.S.), manufacturer of metal and carbon fiber 3D printers, has announced the availability of Onyx FR, a V-0 rated flame-retardant material designed for industries such as aerospace, automotive and defense. Traditional 3D-printed plastics will burn if they catch fire, but this new material is self-extinguishing, so it will actually stop itself from burning. Onyx FR features unmatched strength, superior print quality, high-quality surface finish — all while resisting fire.

Onyx FR is available with Markforged’s Industrial Series printers. Learn more through the company’s .

Onyx FR joins Markforged’s portfolio of industrial metal and composite materials, including the cloud-based software platform Eiger, designed to enable users to design and print remotely. The company recently raised $82 million expand its product line, to include investments into composites fabrication.

“Onyx FR opens up more applications for 3D printing across automotive, aerospace, and defense industries because it meets higher fire safety standards,” says Jon Reilly, VP of product at Markforged. “When these parts are reinforced with strands of continuous carbon fiber, they are as strong as aircraft-grade aluminum at half the weight.”

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

.jpg;width=70;height=70;mode=crop)