Future Composite Manufacturing virtual symposium for AFP and AM

The virtual symposium, held Sept. 9-10, 2020, will focus on current state, trends and opportunities for automated fiber placement (AFP) and additive manufacturing (AM).

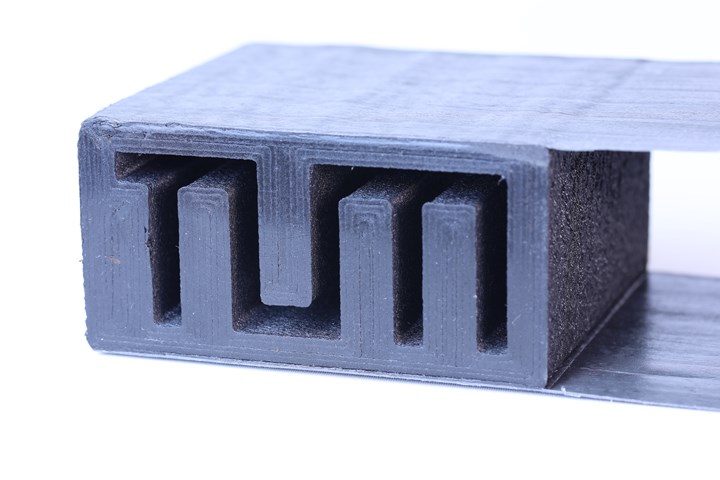

A demonstrator part combining AFP and AM processes.

, a virtual symposium on automated fiber placement (AFP) and additive manufacturing (AM), is occurring Sept. 9-10, 2020 from 10:00 – 17:00 (CEST). The symposium is co-hosted by Technical University of Munich (TUM) and Australian National University (ANU), and supported by Composites United, MAI Carbon, one of the largest networks for fiber-based multi-material lightweight construction, and will discuss the current state, trends and opportunities for research and development in AFP and AM.

Some topics include:

- Additive manufacturing with short and continuous fiber reinforcement, automated;

- fiber placement with in-situ consolidation, industrial applications in the aerospace and automotive;

- industries, functionalization and characterization of composites for AFP and AM;

- and simulation of additive processes.

In addition to ANU and TUM, others will be leading the discussions including AFPT, Airbus (Toulouse, France), BMW (Munich, Germany), CEAD (Delft, Netherlands), the German Aerospace Center (DLR; Cologne, Germany), Fraunhofer (München, Germany), INOMETA (Herford, Germany), SGL Carbon (Wiesbaden, Germany) and Victrex (Thornton Cleveleys, U.K.).

Go to the event website to .

Related Content

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.