First Siempelkamp SMC press system for U.S. customer accepted

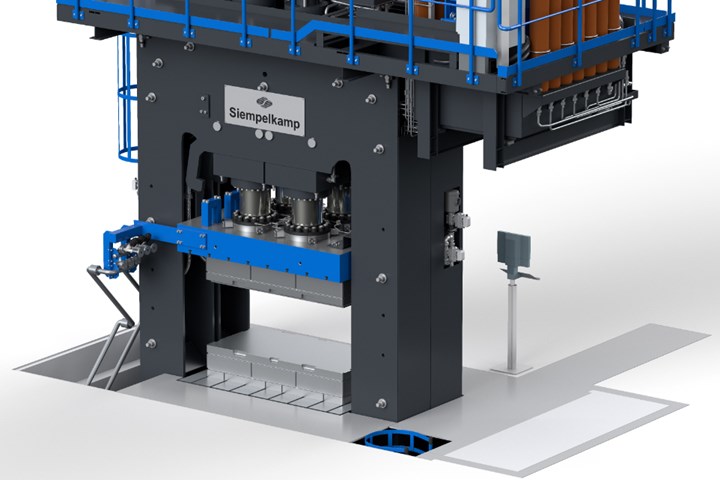

The 1,200-ton sheet molding compound (SMC) press was assembled and commissioned in four weeks.

Source | Siempelkamp

International technology supplier Siempelkamp (Krefeld, Germany), announced on June 26 that its first order placed in April 2019 by a U.S. customer for an sheet molding compound (SMC) press system was accepted and is now in operation. The project’s customer satisfaction represents an important milestone for Siempelkamp, following its three acceptance tests in Russia and Poland.

According to Siempelkamp, the SMC press, which has a press force of 1,200 U.S. tons, was completely assembled and commissioned in Krefeld, Germany, to make the actual commissioning process at the customer's site more efficient. Shipment in a few defined pre-assembly units, including frame packages, hydraulic platform, press table and ram, switchgear cabinets and peripherals, also ensured an optimum, streamlined process flow.

In four weeks, the Siempelkamp teams from the machinery and plants business unit and the machine factory carried out the assembly and commissioning at the customer's site. Siempelkamp says the deployment of its own assembly personnel also contributed to the project’s smooth-running operations.

Siempelkamp says its composites team is proud of this project, especially since the project will represent a special milestone for the U.S. customer in 2019. "These projects confirm the trust that is placed in our composites expertise internationally. It is all the more pleasing that all the acceptance tests were carried out to the satisfaction of our customers," says Sascha Braun, sales manager composites.

Related Content

-

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

-

Testing to support composite bolted joint analysis

An overview of ASTM Standard Guide D8509, and its coupon-level mechanical testing of design properties for analyzing composite bolted joints.

-

Corebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.