Covestro extends cooperation with Sonnenwagen Aachen team for international solar car races

Covestro to remain the main sponsor until 2023 and fund the development of two new sustainable solar cars for future races incorporating bio-based raw materials and recycled plastics.

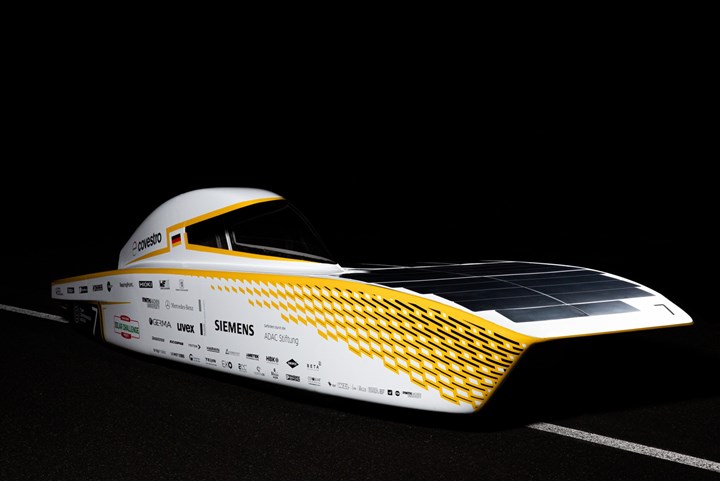

Team Sonnenwagen Aachen and Covestro are jointly looking forward to putting the horsepower of the new “Covestro Photon” on the race track. Photo Credit: Team Sonnenwagen Aachen

In line with its commitment to sustainable future mobility, Covestro (Leverkusen, Germany) is extending its sponsorship — which includes the funding for two new solar cars — of until 2023, a solar race team from RWTH Aachen University and Aachen University of Applied Sciences participating in the .

Despite the cancellation of this year’s race, the Germany-based team developed the solar race car “Covestro Photon,” which has been virtually presented to the public and is set to take part in various races across Europe, the Middle East and the Africa (EMEA) region, including the Solar Challenge Morocco 2021. Using innovative technologies, this new car design is said to be the team’s most efficient one yet.

“I am fascinated by the creativity and entrepreneurial spirit with which the students are developing and optimizing new ideas for solar cars,” says Sucheta Govil, chief commercial officer of Covestro. “That's why we’re sponsoring this project: With our commitment to sustainable future mobility and building a circular economy, we want to encourage young people from top universities to use their talents to work with us to develop advanced materials and technologies.”

Using the Sonnenwagen team’s solar cars, Covestro is testing innovative and sustainable materials under the extreme climatic conditions that typically prevail on such race tracks, including high UV radiation, high temperatures and mechanical vibrations while driving. In addition to partially bio-based raw materials, the company also plans to launch recycled plastics in the next vehicle. According to Covestro, these developments are all part of a comprehensive program to gear itself toward a circular economy.

Related Content

-

Improving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

-

Troubleshooting thermoplastic composite stamp forming

Understand the basic science of TPC stamp forming, a manufacturing process steadily gaining momentum in aerospace and mobility applications thanks to its rapid forming, short cycle times and automated methods.

-

Multi-scale 3D CT imaging enables digital twinning, high-fidelity simulation of composite structures

Computed tomography (CT) provides highly accurate 3D analysis of internal microstructure, performance simulation of carbon fiber/PEEK satellite strut.