Boom Supersonic, JPA Design to develop interior for Overture airliner

Boom Supersonic’s Overture Mach-2.2 supersonic aircraft will travel twice the speed of regular aircraft.

Source | Boom Supersonic

Boom Supersonic (Denver, Colo., U.S.) has announced that it has partnered with JPA Design (London, U.K.), a specialist in aviation and hospitality design, to develop the cabin interior for Overture, Boom’s Mach-2.2 supersonic commercial airliner.

According to Boom, JPA Design’s intention is to create a more “stress-free” passenger experience by tailoring seating options and maximizing cabin flexibility.

Boom is currently assembling XB-1, a Mach-2.2 demonstrator aircraft, to prove key technologies for safe, efficient supersonic travel. The data collected from XB-1 test flights will help refine the design of Overture. See “Is supersonic flight making a comeback?” for more on the project.

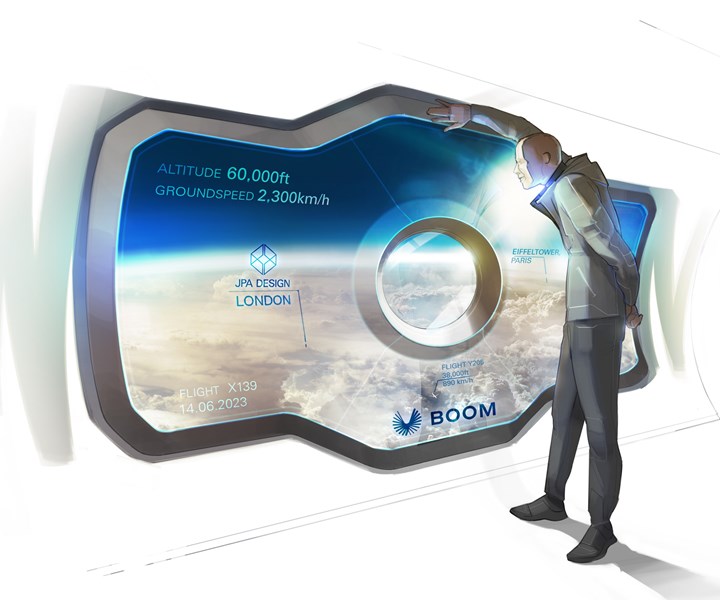

“Our ambition is for travel on Overture to be exceptional in every way. Passengers will fly more than twice as fast as today’s subsonic flights, and they will witness the curvature of the Earth from large, personal windows at 60,000 feet. We are excited to partner with JPA Design to deliver a truly iconic interior design and passenger experience that goes beyond anything commercial aviation has ever seen,” says Blake Scholl, founder and CEO of Boom Supersonic.

“We are deeply excited to partner with Boom, a company that shares our belief in the potential of design and technology to transform how we live and also, our desire to reexamine the entire passenger journey. We are keen to explore how this exceptional aircraft can change every aspect of how we fly,” says Ben Orson, JPA Design’s managing director.

Related Content

-

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

-

The next-generation single-aisle: Implications for the composites industry

While the world continues to wait for new single-aisle program announcements from Airbus and Boeing, it’s clear composites will play a role in their fabrication. But in what ways, and what capacity?

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

.jpg;width=70;height=70;mode=crop)