Beyond Gravity launches startup program “Launchpad”

Incubator supports startups and their early ideas around space technology to lead concepts to seed-funding maturity.

Launchpad program infographic, weeks 1-4. Photo Credit, all images: Beyond Gravity

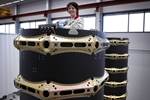

International space supplier, (formerly RUAG Space, Zürich, Switzerland), is launching its own startup program “Launchpad” in October 2022. The incubator will support young startups and their promising ideas around space technology. In the process, teams will be developed from an early stage to an initial investment opportunity. The application period runs until mid-August 2022.

From state-owned enterprises to startup companies, Beyond Gravity says its eight-week startup program at its headquarters in Zürich offers direct access to the international space community. “It is our vision to advance humanity and enable exploration of the world and beyond,” André Wall, CEO of Beyond Gravity explains. “I am very much looking forward to shaping the future of space travel together with selected startups.”

The three focus areas of the incubator include space technology itself, the optimization of value chains and people. Three to five selected teams will be accompanied step by step as they develop their ideas to seed-funding maturity. Finally, a jury of internal and external experts will select the winning projects.

Launchpad project infographic, weeks 4-8.

“All entrepreneurs who are still in an early phase can apply, including those who do not yet have a product on the market,” Stefan Knoche, director transformation at Beyond Gravity, says.

The company invited anyone that sees an unrealized business opportunity related to space technology and its applications, corporate development or sustainability. For those that are interested, please send Beyond Gravity documents, presentations or white papers and a short video (five minutes max) to Stefan Knoche (stefan.knoche@beyondgravity.com) introducing yourself, your partners and your project. The LaunchPad incubator is open to all participants from almost all countries.

Learn more about the .

Related Content

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.