BBG GmbH becomes international system partner for automated production and materials processing

Full-range supplier manufactures supplies for fully automated production modules, molds for composite processes and produces composite components for lightweight construction.

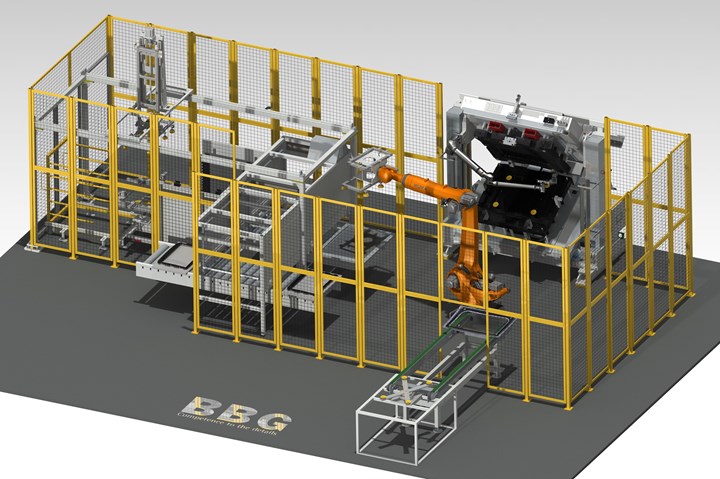

BBG Group is transforming itself from a mold, machinery and plant manufacturer to an international system partner. Photo Credit, all images: BBG.

BBG Gmbh & Co. KG (Mindelheim, Germany) announced on Oct. 28 that it is transforming itself from a mold, machinery and plant manufacturer to an international system partner for polyurethane processing, including glass encapsulation and the production of molded composite components. As a full-range supplier, the manufacturer supplies all components for fully automated, continuously documented production that can be tracked over the entire lifetime of the components. As a general contractor, BBG also retrofits components, or integrates existing equipment into end-to-end production lines. BBG and its subsidiaries target markets in Europe, all NAFTA countries and Asia, China in particular.

As a system partner, the family-owned company also offers to perform all required working steps from a single source. In addition to project planning and plant design, this covers the selection of coordinated modules, including interface coordination and their integration into a central control system. The installation of all components, their commissioning and operator training are also part of the service.

BBG says the modules used cover the work steps for fully automated production lines. They start at the provisioning of materials and the loading of the system, and include the actual manufacturing process and the removal of the produced components right through to visual inspection, post-processing and packaging.

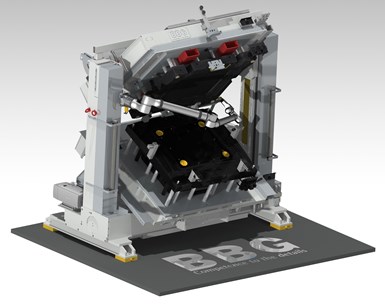

In addition to various individual components — the molds in particular — the mold carrier and press systems are designed and manufactured in the company’s own production facilities. BBG sources other modules from long-standing partners, adapts them to customers’ requirements and integrates them into the production lines.

Further, BBG notes that the degree of automation of a production process can be freely determined, as can the scope of the documentation of material and process data. These are stored centrally and can be retrieved at any time.

Two robot-equipped automation cells are new, which apply release agents to mold surfaces (pictured) and primer or paint to components in an unmanned process.

BBG’s novel solutions consist of two robot-equipped automation cells, which apply primer or paint to components and release agent to mold surfaces in an unmanned process. BBG presented the concept for automatic release agent application using a prototype at its Innovation Day in 2019.

The automation cells reliably improve the quality and process safety of the operations, according to the company. They also relieve employees of work that is physically demanding and sometimes hazardous to their health. The two modules were used for the first time by a North American supplier of passenger car and commercial vehicle parts.

BBG GmbH & Co. KG is an international system partner for the plastics processing industry. In addition to end-to-end production lines, BBG designs, develops and manufactures molds for processing polyurethane, PVC, TPE and other elastomers, as well as a wide range of composite materials. This includes production processes such as PUR composite spray molding (PUR-CSM, long fiber injection (LFI) and resin transfer molding (RTM) for materials such as sheet molding compound (SMC) or glass mat-reinforced thermoplastics (GMT). The company also focuses on solutions for lightweight construction, the processing of composites and the production of fiber-reinforced composite components in a large number of industries. Since 2020, the company has also been developing and manufacturing packaging machines for pharmaceutical products and food supplements.

Related Content

AI-powered robotic solutions support high-mix manufacturing

AI startup offers automation innovations for high-mix, high-variability, manual surface finishing applications.

Read MoreBroetje-Automation demonstrates rCF placement via AFP

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

Read MorePlyable releases AI-powered mold design tool

Plyable continues to rid composites engineers of workflow bottlenecks through an end-to-end automated system — from mold design to quotation to manufacturing fulfillment.

Read MoreMcClarin Composites partners with ExxonMobil to accelerate high-speed RTM

Multimillion-dollar investment to drive next-gen automated RTM technology will open new applications and markets for composites OEMs.

Read MoreRead Next

HP-RTM as a means to reduce hydrogen tank packaging space and cost

BBG Gmbh & Co. KG has developed molds for producers of type IV CFRP tanks, integrating automation and sensors for faster, cheaper production of adjustable-length hydrogen storage cylinders.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More