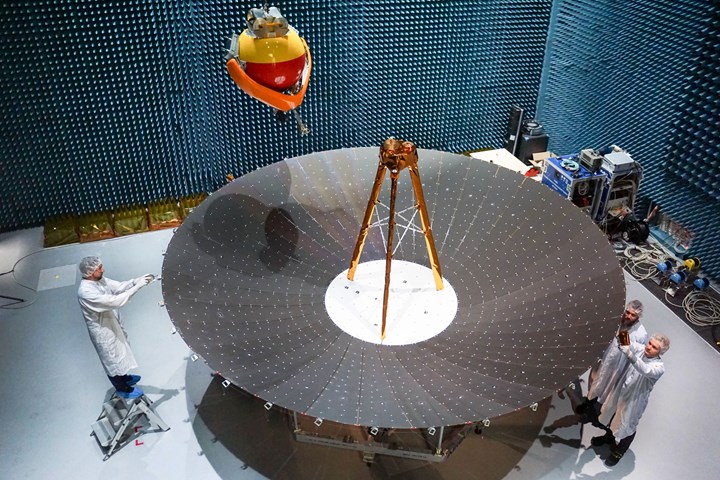

Airbus qualifies Europe's first 5-meter deployable reflector for radar satellites

The unfurlable, parabolic, composite reflector offers significant advantages in satellite deployment and marks Airbus’s entry into the market for cost-effective and small radar missions and constellations.

Photo Credit: Airbus

Airbus (Toulouse, France) reported on Dec. 10 that it has successfully qualified what is says is Europe’s first 5-meter deployable antenna reflector. The 70-kilogram deployable reflector will help enable higher resolution from a radar instrument for Earth observation. Incorporating panels made with high-modulus carbon fiber into the design, Airbus says the semi-rigid reflector technology offers significant advantages compared to classic mesh reflectors.

Due to its large diameter, the reflector would be unable to fit into any rocket fairing, says Airbus. However, this particular antenna reflector is capable of being compactly stowed, and then unfolds like a flower — from 1.6 to 5 meters — after the fairing is released. The unfurlable, parabolic reflector concept enables Airbus to enter the market for cost-effective and small radar missions or constellations.

After successful completion of the intensive deployment and environmental tests, the qualification model has now been delivered to the customer for further tests on the satellite system level. The flight unit will be delivered in 2021 and is currently scheduled for launch for the export customer in 2022.

Related Content

-

Composites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.