Sara Black Senior Technical Editor Emeritus

Looking to lighten up aircraft interiors? Try natural fibers!

Aircraft OEMs are striving to make their products more efficient, with improved engines and ever-increasing use of composite materials, including in aircraft interiors.

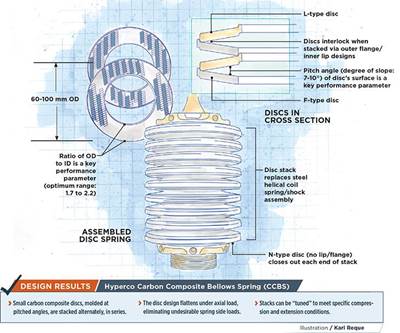

Read MoreCarbon composite spring: Big performance, small package

Disc spring stack is lighter, reduces friction and can be performance-tuned.

Read MoreSummer vacation and MEMS/nanotechnology

Revisiting the past, while the future is happening in my home town.

Read MoreCarbon in the cloud(s)

Carbon is the norm, and even a necessity, at the Pikes Peak International Hill Climb race event, held June 28.

WatchAdditive manufacturing in automotive applications

Although they have been overshadowed by aerospace applications, 3D-printed tools also are finding a place in automotive processing. Here's one example.

Read More3D-printed fixtures & jigs

Holding fixtures, jigs, trim tools and metal-forming dies can be expensive elements of post-mold composite part processing and assembly. Additive manufacturing, therefore, is proving especially useful in reducing the design/build time/cost in this area.

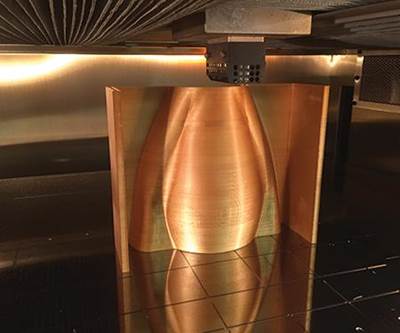

Read MoreA growing trend: 3D printing of aerospace tooling

Toolmakers and OEMs are embracing additive manufacturing for customized, rapid tools, masters and jigs.

Read MoreComposite air brakes: Stopping the world’s fastest car

CFRP sandwich structures a key element of deceleration in the Bloodhound SSC rocket-powered racer’s two-run attempt at resetting the land speed record.

Read MoreComposite engine piston cylinder housings

Phenolic BMC could replace aluminum in car/motorcycle engine housings.

Read MoreSummer...time for an air show

Highlights from the 2015 edition of the Paris Air Show, and what to look for at the upcoming EAA AirVenture air show in Oshkosh next month.

Read More3D Printing Moves Into Tooling Components

Some pundits predict that 3D printing, or additive manufacturing (AM), will change our world forever. While that may yet be, one thing is clear: The growth of 3D printing over the past two decades has wrought significant change in composites tooling. Although AM’s most obvious advantage is direct part production without tooling, the growing trend in the aerospace and automotive sectors at present is its use for fast, on-demand builds of mold tools to keep pace with accelerating composite part design cycles and demand for faster overall part processing speeds.

Read MoreThermoplastic composites technology: A view from Europe

For this Dutch consortium, bringing the manufacturability of thermoplastic materials to maturity is the goal in concert with OEMs, materials and equipment supplier members.

Read More