CW Blog

Strata's workforce leaders share perspectives on women in manufacturing

UAE-based aerostructures manufacturer Strata Manufacturing prides itself on providing opportunities for its multinational, female-dominant workforce.

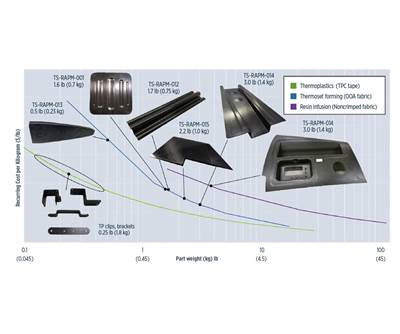

Read MoreRevolutionizing the composites cost paradigm, Part 2: Forming

Boeing-led parts trials explore infusion, compression molding and thermoplastics, offering lessons and supply chain options to better compete with aluminum.

Read MoreCW's Digital Demos, explained

In May 2020, CW is launching Digital Demos, a new on-demand product that provides composites industry suppliers a channel to introduce new products and technologies to the CW audience of designers and fabricators. This video briefly explains it.

WatchMaterial choices for the Corvette rear bumper beam

From fabrics to resins, a number of new combinations of materials went into the making of the world’s first curved pultruded automotive part.

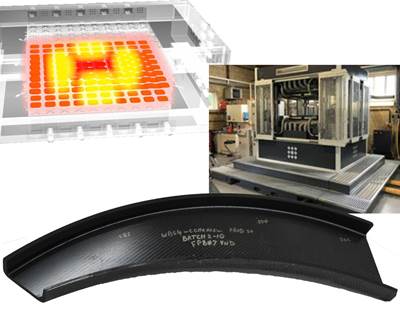

Read MoreRAPM development with PtFS

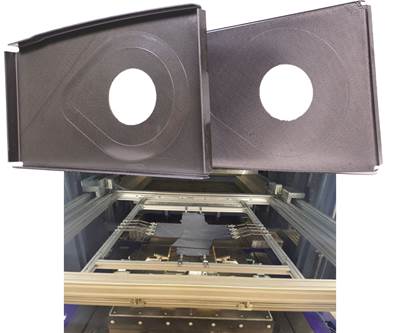

Boeing-led program explores rapid part cycles using automated, 180-channel thermal control molding cell for infusion, thermoset prepreg and thermoplastic composites.

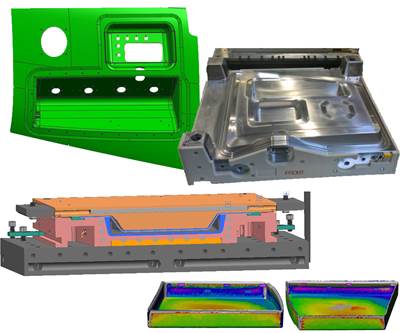

Read MoreManufacturing the complex geometry parts of RAPM

Boeing-led program explores simulation, tooling, preforming and molding approaches to lower composites part cost.

Read MoreNovel prepreg for compression molding in RAPM

Solvay and Boeing combine aerospace performance with process knowledge for high-rate, low-cost composites production.

WatchCurve in the road: First curved pultruded auto parts

Thomas Technik + Innovation KG’s radius pultrusion process unlocks new possibilities for the automotive market and beyond.

Read MoreCurved pultrusions enter production

Corvette CFRP rear bumper beam is the auto industry’s first use of new technology.

Read MoreWhat will the composites industry's post-pandemic future look like?

We already have the tools needed to help us craft our future, even if we do not know yet how and where those tools might be deployed.

Read MoreDeveloping new solutions for noise, vibration and harshness

Several recent IACMI partner projects focus on technology innovation related to challenges in noise, vibration and harshness (NVH) in vehicle design.

Read More