CW Blog

Tours and Technology Trends in 2022: CW Trending Episode 9

It has been a busy year for the CW team. In episode 9 of CW Trending, editor-in-chief Jeff Sloan and senior technical editor Ginger Gardiner discuss their recent plant tours and trends in the industry.

Read MoreThermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

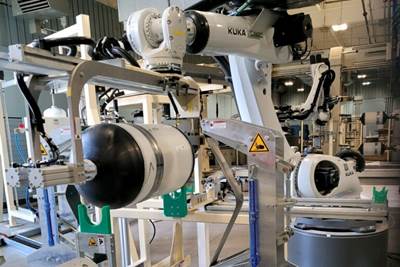

Read MoreAutomated filament winding system increases throughput, reduces manual labor for pressurized well tank production

For its new line of composite well water tanks, Amtrol worked with Roth Composite Machinery on an automated process for faster, more easily tracked production.

WatchComposites enable epic interior for Museum of the Future

For this one-of-a-kind lobby, AFI pioneered digital, reconfigurable molds to achieve organic-shaped, multifunctional panels and stairwell cladding.

WatchAdvanced Fiberglass Industries: Composites enable innovation

With decades of composites design and fabrication experience, Dubai-based AFI turns problems into solutions.

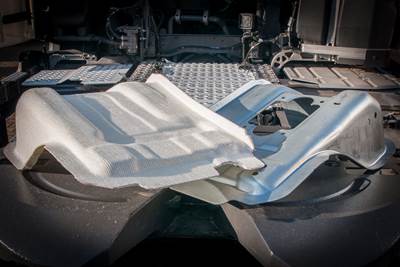

WatchOne-shot manufacture of 3D knitted hybrid thermoplastic composite structures

MAPICC 3D project replaces steel seat support in heavy-duty vehicle with a 3D knitted composite made from thermoplastic hybrid yarns comprising the matrix and reinforcing components.

Read MoreWhy does my composite mold leak under vacuum or applied pressure?

Louis Dorworth of Abaris Training Resources outlines key considerations to make when fabricating quality composite molds to minimize risk of leakage under pressure or vacuum.

Read MoreMitigating Carbon Fiber Emissions for Fabricators

Thermal or catalytic oxidation devices are capable of achieving over 99% destruction of the emissions from carbon fiber manufacturing. Recent developments in these technologies have improved efficiency, effectiveness, process uptime, and reduced carbon footprint.

WatchPrefabricated composite panels, joining system ease catamaran construction

New Zealand-based G&T Marine reduces assembly and construction time with ATL Composites’ composite DuFLEX panels.

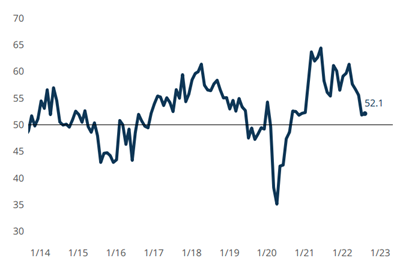

Read MoreComposites industry GBI holds its own in August

The GBI: Composites Fabricating ended August with slowed expansion but managed to stay above water, with all component indices continuing to show slowed rates of growth.

Read MoreUniFORM: High-quality, high-complex EV battery enclosures at low cycle times, low tooling costs

Stellantis subsidiary CpK Interior Products Inc. recently completed a design challenge to prove out its vacuum-assisted wet compression molding process for CFRP battery trays.

Read MoreWelcome to the Composites Age

The human race has a long history of developing materials, each one a little better than the one before it. Composites are among the latest in a long line, and proving highly adaptable to new opportunities.

Read More