RocTool composite demo at K 2016

In partnership with Flextronics and Arburg, the RocTool new technology combines the forming of a composite sheet and injection overmolding of thermoplastic in the same process.

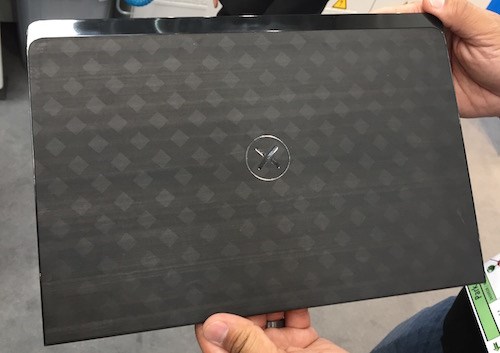

RocTool is showcasing its latest molding technologies at K 2016. The company has several demos throughout the show including one of its Induction Dual Heating (IDH) process, a combination of plastic and composite materials with the new RocTool heating configuration. In partnership with Flex and Arburg, the RocTool new technology combines the forming of a composite sheet and injection overmolding of thermoplastic in the same process. RocTool presented the process for a "hybrid" 14-inch computer cover that is 1.0 mm thick, bringing the benefits of composite (high modulus, lightweight) and plastic (cosmetic integration functions integrations) in one and the same product while eliminating secondary operations. This is done in a 1-minute cycle time per part and in the same machine. Pretty cool technology. Here's the computer cover:

Check out video of the process below:

Related Content

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.