Next-generation pressure vessels in space

After a name change, next on the horizon for Infinite Composites Technologies is supplying Type V tanks to the space race.

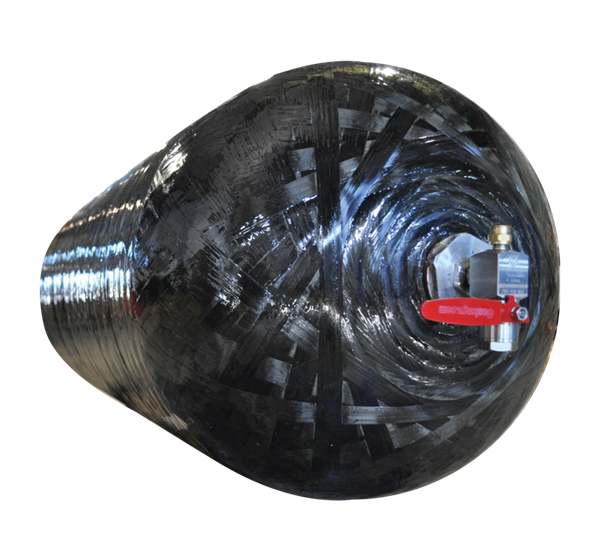

Infinite Composites Technology has developed a patented infinite composite pressure vessel or infiniteCPV (iCPV), which is a Type-5 (Type V), liner-less all-composite vessel.

For Infinite Composites Technologies (ICT), Tulsa, Okla., it all began as students at Oklahoma State University (OSU) in Stillwater, Okla. In 2008, ICT founders Matt Villarreal and Michael Tate become part of a collegiate race team at OSU that raced under the Formula Society of Automotive Engineers (FSAE). The race team was in need of help. When the duo joined, there was $56 in the account to design and fabricate a quarter scale Formula-1 style race car and take it to competition in Fontana, Calif. Eventually, Villarreal and Tate pushed for converting a vehicle to run on compressed natural gas (CNG) to attract new investors from local natural gas players. By 2010, the team successfully converted a vehicle to CNG with the assistance of Tulsa Gas Technologies and other supporting sponsors. And later that year, the founders formed CleanNG LLC. In 2015, the company changed its name to Infinite Composites Technologies to diversify itself and embrace its abilities to provide broader storage options for a larger customer base.

The company created a patented infinite composite pressure vessel or infiniteCPV (iCPV), which is a Type-5 (Type V), liner-less all-composite vessel. The infiniteCPV’s all-composite design allows for users to take advantage of the maximum fuel storage capacity while lowering the weight. Traditional liners take up valuable storage space and reportedly add unnecessary weight. The iCPV provides 10% more useable volume while reducing weight by 90% compared to traditional vessels. And while the company has a focus on developing next-generation fuel storage and delivery systems for natural gas vehicles and storage applications, it has recently been gaining traction in the adoption of a Type V tank technology to the space industry.

ICT says that replacing heavy metallic structures with composites will enable the growth of space exploration by reducing fuel requirements, creating reusable rockets and lowering the cost to send goods into orbit. The company has worked with NASA and Yeti Space and is currently testing and developing propellant tanks for a confidential space company using the iCPV technology.

And with a plethora of startups from SpaceX to Blue Origin, there is a lot of movement in the space race and ICT sees an opportunity as these companies need high-pressure gas storage tanks. Every rocket uses a range of tank sizes for various needs from propulsion to breathing systems, but the one common goal each of these companies is to have the lightest system possible. After all, every pound saved on the high-pressure fuel systems can generate fuel savings. It also helps in reduced launch prices, which are currently at an all-time low because of reusable rockets. (For more on this topic, check out ).

Related Content

-

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

-

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.