Articles

A350 & A400M wing spars: A study in contrasts

In three short years, GKN Aerospace has taken its wing spar manufacturing strategies to new heights by dramatically reducing part weight, process complexity and production-cycle duration.

Read MoreNondestructive inspection: Better, faster and cheaper

Faced with new time and cost pressures, NDI system suppliers are integrating inspection with manufacturing to reduce its share in part cost and cycle time.

Read MoreCeramic matrix composites heat up

Lightweight, hard and stable at high temperatures, CMCs are emerging from two decades of study and development into commercial applications.

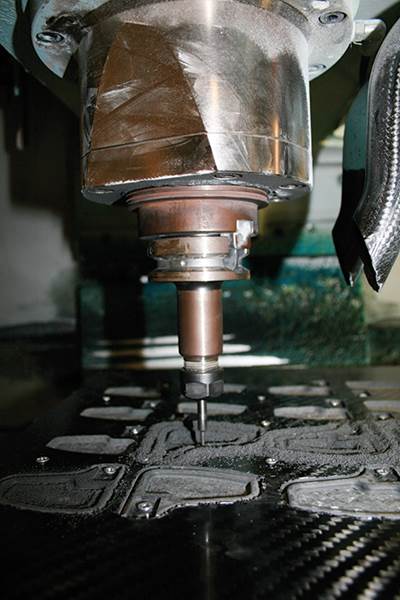

Read MoreSoftware supplier aids parts producer with greater accuracy

Paul Crosby (Crosby Composites, Brackley, Northamptonshire, U.K.) says PowerMILL software, which converts CAD models to NC toolpaths for multiaxis milling, has helped produce F1 composite parts to levels of accuracy rarely seen in the industry.

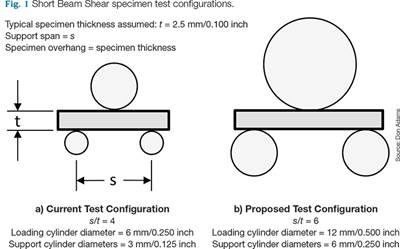

Read MoreThe Short Beam Shear test method for composite materials

Dr. Donald F. Adams (Wyoming Test Fixtures (Salt Lake City, Utah) suggests larger support and loading cylinders for the Short Beam Shear test method.

Read MoreToray + Zoltek = potential game changer?

Consultant Dale Brosius, also president of Dayton, Ohio-based Quickstep Composites LLC, the U.S. subsidiary of Australia-based Quickstep Technologies (Bankstown Airport, New South Wales), sees the Toray buyout of Zoltek as a potential auto-industry game changer.

Read MoreCo-infused stringers and carbon fiber at Ft. Lauderdale Boat Show

Midnight Express Boats takes almost 4,000 lb out of its newest model, the 39S, with a switch to infusion and better optimized laminates.

Read MoreC-Series composite wing

The C-Series and Learjet 85 feature wing structures manufactured with dry fiber placement, but with cure in an autoclave. CW looks at how it's done.

Read MoreToray makes waves with Zoltek purchase

Toray was already the largest carbon fiber maker in the world, and with Zoltek it not only gets bigger, but expands into new markets.

Read MoreStructural preform technologies emerge from the shadows

Not yet in full production, with one exception, all are aimed at accelerating composite part manufacture at fast automotive rates.

Read MoreWind blades: Progress and challenges

Despite double-digit wind energy industry growth, turbine blade manufacturers and materials suppliers acknowledge a pressing need to reduce costs and innovate.

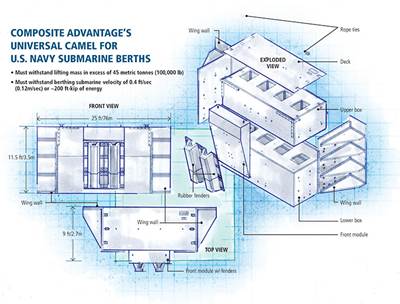

Read MoreComposite submarine camels win with long-term durability

U.S. Navy wisely opts for more expensive submarine moorings that maximize lifecycle cost efficiency.

Read More