The IO carbon fiber white cane, developed by Whitecane and produced in cooperation with Refitech and CG Tec, is extremely lightweight, making the cane easy to handle, reducing fatigue and the risk of injury, while improving sensory perception. Photo Credit: Whitecane

(Duderstadt, Germany) is a company with a goal of designing and developing high-quality, technically sophisticated medical products, with a focus on equipment to aid the visually impaired. Supported by composite engineering and production specialist (Waalwijk, Netherlands) and partner (Spalt, Germany), Whitecane has developed and launched IO, an innovative white cane featuring a lightweight, easy-to-handle composite tube structure and ergonomic, carbon fiber grip.

The partnership, according to Bas Nijpels, sales engineer at Refitech, began in 2018. “The cooperation came about when we purchased carbon tubes for our first prototypes from the CG Tec web shop,” adds Lüder Mosler of Whitecane. When Whitecane began to look for a partner to design a carbon grip for the cane, CG Tec, which had formed a strategic partnership with Refitech in 2018, recommended Refitech. “Both companies have shown a great willingness to respond to our very specific technical and economic requirements, and find good solutions together,” Mosler says. “This has resulted in a highly innovative carbon fiber white cane that has no match in the current market.”

The ergonomics of the IO white cane are enhanced by a curved handle that follows the natural hand position, while the cane can be easily folded and unfolded even in tight spaces. Photo Credit: Whitecane

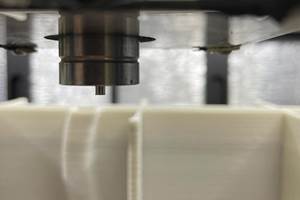

The ergonomics of the IO white cane are enhanced by a curved handle that follows the natural hand position, while the cane can be easily folded and unfolded even in tight spaces. Photo Credit: WhitecaneCG Tec supplies the carbon fiber/epoxy prepreg tubes, which are manufactured in a semi-automatic process of winding prepreg around mandrels, and assembles the canes in batches at its Spalt facility. “In a first conversation, the idea and the background of the IO white cane were introduced, and this immediately triggered our enthusiasm,” says Oliver Kipf, CEO of CG Tec. “Based on Whitecane’s requirements, we first developed carbon fiber tubes that could withstand the expected pressure loads in combination with a high bending stiffness. The tight tolerances were a challenge, but we solved that in the end.” The much greater stiffness compared to a standard cane, Nijpels explains, enables a sturdier contact and better experience and feel for the user.

In addition to stiffness, Nijpels says, two of Whitecane’s top requirements for the design were ease of assembly and affordability for the consumer. “Our engineers worked closely with Whitecane and CG Tec on the design, giving advice and having regular meetings to discuss the project progress,” Nijpels says.

For the carbon fiber grips, Refitech needed to develop a “mirrored” design, Nijpels says, that could be manufactured for both right- and left-handed users. For this project, the company used its experience designing similar products for medical and consumer applications, such as a carbon fiber guide dog handle that was a finalist for a JEC 2019 Innovation Award. The white cane grip is manufactured from a twill-weave carbon fiber/epoxy prepreg over top of an additional layer of unidirectional (UD) fabric. The parts are manufactured via a blow molding process followed by autoclave cure. “This allows for a lightweight, thin-walled part, allowing us to manufacture in series production at a reasonable cost,” Nijpels says.

The grip is connected to the rest of the cane via a specially designed bracket. The design also features a lightweight rolling tip and a patented yield mechanism that immediately folds the cane upon impact with an obstacle, reducing the risk of injury due to a collision. IO can also fold into three segments for easy transport and storage.

“This application clearly demonstrates the potential benefits that 3D-formed carbon components can bring: an integral solution designed and produced with innovative materials, ensuring an immediate competitive edge over the competition,” Nijpels says.

Whitecane launched IO to the German medical market in early 2020. Next steps include expanding certifications for the product in other countries and expanding IO’s distribution network with additional partners. Over the next few years, Whitecane also plans to scale up production of the product, from current batches of 100 parts per shipment to up to 700 per batch.

Related Content

Pull-wound fiberglass composite 5G utility poles enable easier, faster installation

EasyStreet Systems is working with Exel Composites to develop and certify pull-wound fiberglass utility poles aimed at durable, lightweight poles for 5G small cell systems.

Read MoreOptimized rib-reinforced hollow composites via printed molds

Addyx topology optimization and water-soluble mandrel enables simultaneous rib and skin layup for one-shot, high-strength, lightweight structures.

Read MoreMold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

Read MorePull-wound carbon fiber poles enable lightweight, compact, rigid emergency stretcher

Based on military feedback, Epsilon Composite developed an optimized, foldable stretcher that combines telescopic pull-wound carbon fiber tubes.

Read MoreRead Next

Refitech launches carbon fiber composite telescopic tube

The lightweight RefiFLEX TS pole22 is said to be ideal for carrying audiovisual equipment and applications in the hospitality and medical industries.

Read MoreCG TEC and Refitech partner on composite components

CG TEC has signed a strategic partnership agreement with Refitech.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More

.jpg;width=70;height=70;mode=crop)