VOC-free UV curing prepregs, putties and primer provide effective repair, bonding

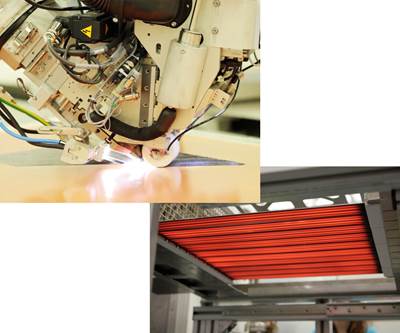

CAMX 2024: Sunrez Corp. presents its product line for UV curing, all crafted without VOCs or HAPs for reduced emissions.

Share

Sunrez Corp. (El Cajon, Calif., U.S.) is featuring its custom 7355 VOC-free products for ultraviolet (UV) cure. These products include prepregs, putties and primer. When used in combination, they can effectively repair and bond composite and metal structures in minutes instead of hours, the company reports.

Sunrez’s 7355-vinyl ester prepregs offer single-component pre-impregnated fiberglass fabrics with long-term shelf stability and working time, as well as rapid cure without any requirement for post-cure. Standard fabrics include 1,000 gsm UD, 900 gsm Combi and 800 gsm Biax, as well as chopped strand mat and surf cloths. According to the company, these prepregs are ideal for field repairs where enhanced strength and corrosion resistance are desired.

The Sunrez 1022 primer can provide optimal adhesion to aluminum, steel, ABS, PVC and any composite surface with minimal surface preparation. No VOCs or HAPs are present, so no emissions are created.

All Sunrez products are one-component, so no mixing or wetout is required on-site. No shipment of flammable resins or peroxides are required, as well. Moreover, no special storage requirements are needed because working time is measured in days if the materials are kept out of sunlight. Cure times, either by sunlight or by Sunrez’s UV lights, are said to take less than 10 minutes and are insensitive to temperature changes. No post-cure is needed to achieve a complete cure, according to the company, and its vinyl ester backbone provides enhanced mechanical and thermal properties, as well as optimal chemical resistance and flame spread performance.

These fabrics and mats are available in various customizable sizes, from a few inches up to a full meter in width.

Related Content

-

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

-

Plant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

-

Reinforcing hollow, 3D printed parts with continuous fiber composites

Spanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.

Related Content

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MorePlant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

Read MoreReinforcing hollow, 3D printed parts with continuous fiber composites

Spanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreRead Next

Techonologies for UV curing of composite laminates demonstrated

Racing go-kart project demonstrates advances in UV processing of composites.

Read MoreInnovating energy delivery for more efficient composites manufacturing

Heraeus Noblelight develops HUMM3 and Black IR technologies for faster, safer, more uniform processing.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More