Specialty materials supplier supports quality project execution

CAMX 2025: Smooth-On highlights its leadership in specialty materials, custom formulations and hands-on project expertise, available to composites customers in a variety of industries.

Share

Source | Smooth-On

Since 1895, Smooth-On (Macungie, Pa., U.S.) remains a dynamic, family-owned U.S. manufacturer of specialty materials — silicones, epoxies and release agents, etc. — used for a variety of applications across different industries and shipped globally. Smooth-On offers more than 80 years of materials leadership in aerospace, marine and motorsports applications and has custom formulation capabilities.

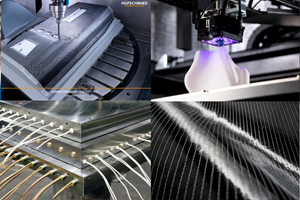

From prototyping a lightweight UAV component to laying up high-temperature autoclave tooling, Smooth-On says it delivers every chemistry needed under one trusted roof. The company’s sprayable and brush-on silicones capture intricate details while resisting the aggressive resins and cure cycles demanded by carbon fiber, fiberglass and Kevlar layups. Step directly into production with Free-Form Air HT or EZ-Spray Silicone 20 — products that eliminate pattern-making time and extend mold life, reducing cost per part.

When strength and dimensional stability matter, Smooth-On suggests EpoxAmite laminating epoxies and EpoxAcoat gelcoat systems. These low-viscosity, low-exotherm epoxies wet out reinforcement quickly, cure bubble-free and hold tight tolerances at high service temps. Pair them with Ease Release or Price Driscoll release agents for easy demolding and a showroom-finish surfaces.

Because every program is unique, Smooth-On’s portfolio spans Shore 10A silicones to 90D epoxies, enabling customers to dial in durometer, pot life and high-temp performance. Its hands-on support team, comprising experience material experts, are available to discuss project needs.

Smooth-On has 400,000 square feet of manufacturing space, six U.S. warehouses and 160 global distributors, all aiming to cut lead times and keep critical programs on schedule.

Related Content

-

VIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

-

CAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

-

Repurposed carbon fiber waste support closed-loop recycling goals

CAMX 2025: Work with Carbon Fiber Conversions, a supplier and a strategic partner, to transform carbon fiber waste into a valuable resource, strengthening both business and sustainability credentials.

Related Content

VIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

Read MoreCAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

Read MoreRepurposed carbon fiber waste support closed-loop recycling goals

CAMX 2025: Work with Carbon Fiber Conversions, a supplier and a strategic partner, to transform carbon fiber waste into a valuable resource, strengthening both business and sustainability credentials.

Read MoreAutomated RTM, SQRTM enhance aerospace composites serial production transition

CAMX 2025: Coexpair, in partnership with Radius Engineering, combines equipment development and fabrication with engineering of composite parts, demonstrated in its European customer support, deliveries.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More