Hybrid mold release agent offers paste wax simplicity with semipermanent performance

CAMX 2025: Chem-Trend’s 2775W represents a solution for composites manufacturers who want high performance without the operational changes required by solvent technologies.

Share

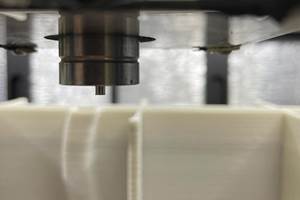

Source | Chem-Trend

Chem-Trend (Howell, Mich., U.S.) introduces a solution for composites manufacturers looking to move away from the labor-intensive demands of traditional paste wax but aren’t ready or able to make the jump to solvent-based semipermanent mold release systems.

Chem-Trend’s 2775W is a one-part water-based hybrid release agent that delivers multiple releases per application in a nonflammable, VOC-free and PFAS-free formulation. Developed in response to direct feedback from customers, this innovation provides a Class A surface finish with less effort and downtime compared to paste waxes.

The release agent mimics the familiar application process of paste wax, making it ideal for operations not yet equipped to convert to solvent-based systems. It can be sprayed or hand-applied with a clean cotton cloth, then left to flash off into a light haze before a simple buff by hand — no mechanical buffing tools or long cure times required.

Once in production, Chem-Trend reports that the hybrid release can offer up to four times more releases between touch-up coats than conventional paste wax, providing gains in efficiency and consistency. At the same time, it minimizes build-up on the mold surface, helping maintain surface quality over time.

Attendees are able to see this hybrid release agent in action and explore additional innovations, including silicone-free release solutions and next-generation high-build primers designed to improve surface quality and process throughput.

Related Content

-

VIDEO: Enhancing composite tooling with additive manufacturing

At JEC World 2025, CW editor-in-chief Scott Francis explored the latest advancements in composite tooling with Massivit and Sika.

-

Mold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

-

DLR study considers cast PA6 molds for in situ AFP composites

3D printed thermoplastic mold was analyzed as alternative to expensive, time-consuming metallic molds and for suitability in aerospace-grade composite structure fabrication.

Related Content

VIDEO: Enhancing composite tooling with additive manufacturing

At JEC World 2025, CW editor-in-chief Scott Francis explored the latest advancements in composite tooling with Massivit and Sika.

Read MoreMold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

Read MoreDLR study considers cast PA6 molds for in situ AFP composites

3D printed thermoplastic mold was analyzed as alternative to expensive, time-consuming metallic molds and for suitability in aerospace-grade composite structure fabrication.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More