Thermoplastics

Toray, Daher and Tarmac Aerosave announce End-of-Life Aircraft Recycling Program

Collaborative initiative aims to reuse secondary structural TPC parts from EOL Airbus A380 aircraft and repurpose them for other aeronautical applications in order to collectively advance TPC recycling technologies.

Read MoreAerospace manufacturing innovations demonstrate the future of aerocomposites

CAMX 2025: Attendees are able to explore several of NIAR ATLAS’ prototype developments in person, highlighting tool-less space manufacturing, AI-enabled inspection and repair and thermoplastic overmolding.

Read MoreThe AMRC announces U.K. open-access TPC tape development

Dedicated research platform, available to businesses and researchers at the AMRC’s Factory of the Future facility, features Cygnet Texkimp’s hybrid line and tape slitter on a pilot scale.

Read MoreXenia presents Xeramic ceramic thermoplastic fillers

Compounds range, available in the Pure version and the fiber-reinforced Core version, are an addition to Xenia’s product solutions featuring high thermal conductivity and heat dissipation.

Read MoreHRC highlights automotive material innovation, scalable manufacturing and sustainable systems

The composites company is meeting the transition to electrification and vehicle lightweighting via hybrid monocoques, use of thermoplastic composites and carbon fiber and recycling.

Read MoreAdvancing thermoplastic composite primary structure and morphing wings

The HERWINGT project in Clean Aviation seeks to ready technologies — including at least 16 composite demonstrators — for a hybrid-electric regional aircraft with 50% less fuel burn to be launched by 2035.

WatchOligomer polymer engineering transforms 100% recyclable thermoplastic composite paradigms

MET-OL thermoplastic technology alters high molecular weight polybutylene terephthalate into low-viscosity oligomers, enhancing fiber impregnation and catalytic repolymerization for fully recyclable, high-performance composites.

Read MoreThe new Slate truck costs less than $20,000, uses PP composite body panels

Stylish vehicle EV pickup model is supported by a simplified manufacturing process. It is also capable of customization from two seats to five seats.

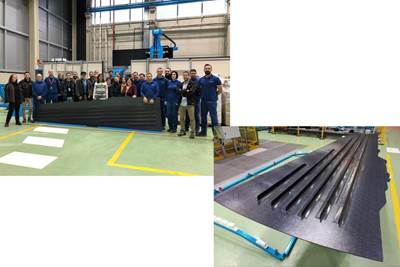

WatchTAVieDA project team cuts aircraft door production time using thermoplastic composites, welding

Fraunhofer groups, Trelleborg and Airbus develop modular, fully automated assembly system concept to replace metals and time-consuming assembly that shows potential for scalability.

Read MoreAimen contributes to OVERLEAF 3D printed cryogenic tank

Dual thermoplastic composite system, developed to withstand temperatures below -250°C, demonstrates aviation decarbonization strategies.

Read More