Thermoplastics

Leichtbau ist hybridbau

Integrating multiple materials and functions for lightweight construction in the German automotive industry.

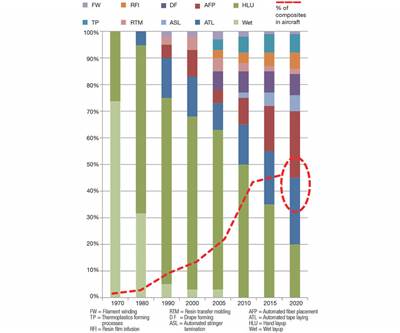

WatchThermoplastics in Aerospace Composites Outlook, 2014-2023

Capable of volume production, thermoplastic composites will gain new market share in the aerospace industry.

Read MoreAre LFRT composites key to auto adoption?

Long carbon fiber-reinforced thermoplastics don't pack the punch of continuous carbon fiber, but they might help spread use of composites in automotive.

Read MorePolystrand, PPG and SANLUIS Rassini collaborate on lightweighting technologies

The three companies join forces to prepare a sports car to showcase continuous fiber thermoplastic composites technologies. The car will compete in SCCA's GTL class.

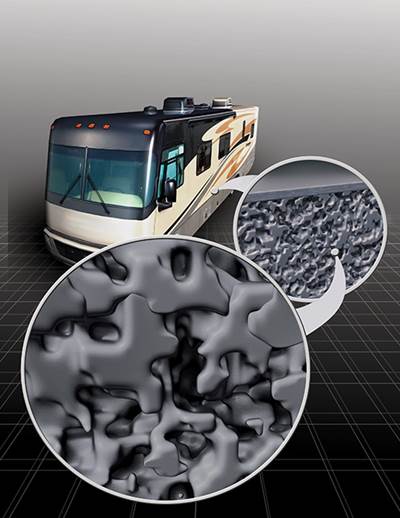

Read MoreMass reduction for mass appeal: FRPs and CMCs in RVs

Composites save weight, speed assembly, improve aesthetics and diminish warranty service and promote sales.

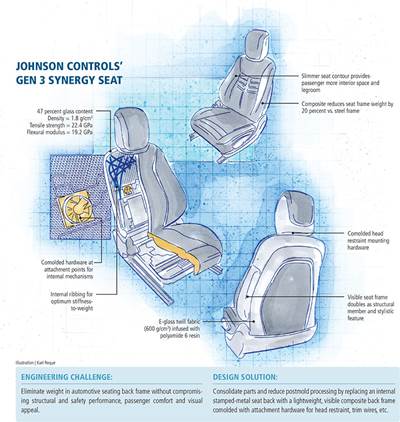

Read MoreSitting pretty: Car seat concept scores a first

Automotive supplier’s reinforced thermoplastic back frame curtails weight and simplifies molding/styling tasks.

Read MoreTAPAS 2: Next steps in thermoplastic aerostructures

The Netherland's-based Thermoplastic Affordable Primary Aircraft Structure (TAPAS) consortium's TAPAS 2 team builds on the successes of TAPAS 1, taking the next steps in aircraft thermoplastic composites architecture.

Read MoreORNL demonstrates 3-D printing with carbon fiber

Oak Ridge National Laboratory can print carbon fiber reinforced parts from 10 cm in size up to 2.4m in both lab and production settings at its Carbon Fiber Technology Facility.

Read MoreMolding i3 body panels

Beyond its CFRP Life Module, BMW's i3 commuter car features doors, door inners, fenders, bumpers, a hood and a rear spoiler made from injection molded thermoplastic.

Read MoreMove over honeycomb, thermoplastic sandwich is commercialized as DYNATECH

PEI foam core/skin sandwich panels claim to save up to 40 percent weight and 30 percent cost in rail and aircraft interiors vs. honeycomb.

Read More