Sensors

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

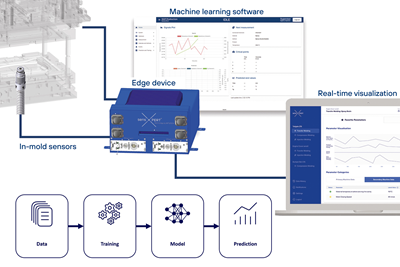

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

WatchHBK enhances sensor offerings with MicroStrain acquisition

MicroStrain designs and manufactures high-precision inertial and wireless sensing systems that cater to industries such as automation, mobility and unmanned vehicles.

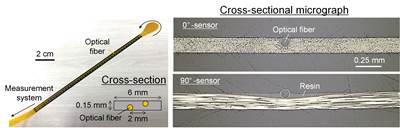

Read MoreUniversity of Southampton develops miniaturized optical fiber condition monitoring technology

A more compact, affordable strain interrogator, currently developed for FBG monitoring, may enable more widespread adoption of optical fiber sensing used in composite materials.

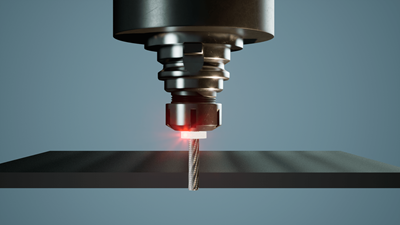

Read MoreTemperChip machining temperature sensor for composites

Patented device provides real-time machining data to monitor and accurately predict tool life, opening up the horizons to measure a variety of parameters between cutting tool and material.

WatchMeasuring ply-wise deformation during consolidation using embedded sensors

Strip-type shape sensor method claims real-time measurement of ply-wise deformation.

Read MoreUD researchers advance TuFF composite's viability for aerospace

The University of Delaware’s research team continues to mature the short fiber composite’s cost competitiveness with metal through sensor embedding, virtual modeling and TuFF thermoset manufacture.

Read MoreINFINITE consortium tackles wireless sensor integration for life-long aircraft monitoring

Engineers from University of Sheffield AMRC will support the embedding of highly specific sensors into composite aerospace structures for MHM and SHM and recylability opportunities.

Read MoresensXPERT Digital Mold earns 2022 AVK Innovation Award

Data-driven sensor technology optimizes and increases composites manufacturing efficiencies in real time, achieved through collaborative network.

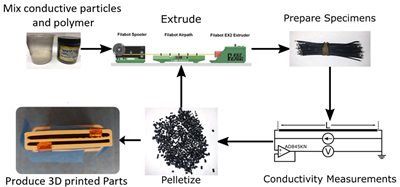

Read MorePatent-pending Purdue process embeds sensor particles, functionalizes 3D-printed structures

Purdue University researchers have developed a novel wet-mixing method to add sensor particles to 3D printer filaments, which will enable manufacturers to create functional printed parts.

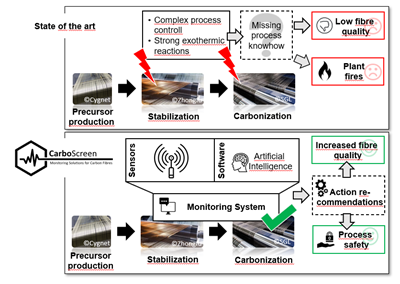

Read MoreCarboScreen project to develop multimodal, sensor-based monitoring of carbon fiber production process

January 2023 CarboScreen project seeks to improve carbon fiber yield, reduce cost and improve properties.

Read More