Sensors

MoistTech Corp. introduces IR3000 moisture sensors

Near infrared (NIR) sensors deliver precision moisture control and reliable moisture analysis for natural fibers, synthetic fibers and blended fabrics.

Read MoreThe evolution, transformation of DEA from lab measurements to industrial optimization

Over the years, dielectric analysis (DEA) has evolved from a lab measurement technique to a technology that improves efficiency and quality in composites production on the shop floor.

Read MoreVIDEO: AI, cameras and lasers for FOD detection

Virtek Vision demonstrates its Iris AI technology at CAMX 2024. It combines laser projection with machine learning software to detect foreign object debris during a composite layup.

WatchStreamlining aerospace composites operations with RFID tracking

Tier 1 Sekisui Aerospace’s implementation of RFID tracking, sensors and Xemelgo software at two of its production facilities led to increased productivity, eliminating bottlenecks and reducing labor costs.

WatchTPI, University of Texas participate in wind blade cure optimization project

Physics-informed machine learning algorithms will be applied to simulate and optimize composite wind blade curing in an effort to advance smart composites manufacturing in industry.

Read MoreRVmagnetics introduces R&D service for MicroWire technology

RVmagnetics now enables the development of composite measurement and monitoring systems based on its passive sensor technology, to fit exact customer requirements.

Read MoreTechnology Marketing Inc. to distribute VacPuc digital sensors

VacPuc is expanding its range of global distributors to deliver its vacuum pressure measurement solution to the composites market.

Read MoreGill highlights custom sensors expertise with industry flexibility

Product offering encompasses specialist level sensing, condition monitoring, position sensors and engine control products for composites-based applications.

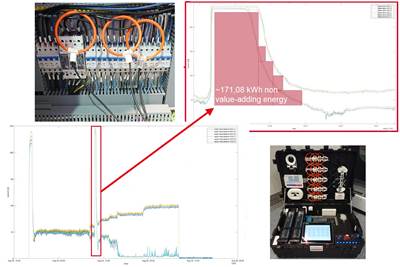

Read MoreMeasuring energy use to enable sustainable composites production

Airbus subsidiary CTC uses new technology to measure energy use in machine components and processes to optimize equipment, production lines and guide decisions for future composites.

Read MoreU.K. academics head up flat fiber sensor research for composites

Six universities are in charge of developing flat fiber sensors, which will then be applied with industry partners, to determine their impact in monitoring composites manufacturing and more.

Read More