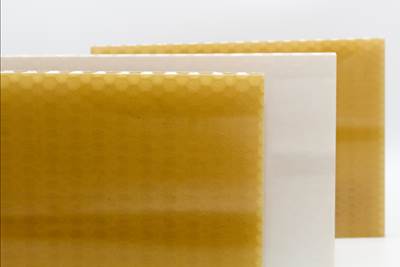

Resins

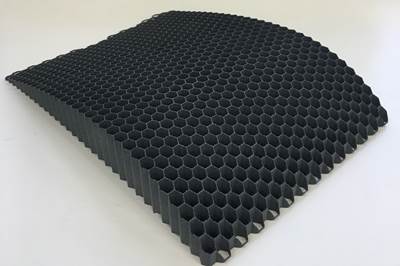

EconCore, Toray and Bostik collaborate on FST-qualified thermoplastic honeycomb panels

Developed for mass transportation applications, including aircraft interiors, the material improves upon the cost, sustainability and versatility of conventional sandwich layup.

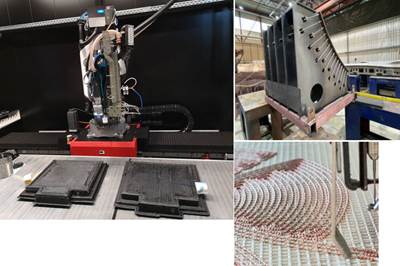

Read More3D printing CFRP molds for RTM flaperon, exoskeletons and more

The Chair of Carbon Composites at TU Munich is advancing composite additive manufacturing via large-scale extrusion, continuous fiber printing, integrating heating into tools and more.

Read MoreMITO Material Solutions raises $1 million for graphene-functionalization

The developed additives are said to enhance fiber-reinforced composites and thermoplastics up to 135% beyond standard metrics for replacing metals.

Read MoreLanxess extends use of composites to extrusion blow molding

The process demonstrates its capabilities to boost the mechanical performance of blow-molded components in high-stress areas.

Read MoreCompoTech launches standard range for carbon finer epoxy beams

Produced via AFP and precision press molded results in a high-strength carbon epoxy composite beam with 10-15% higher stiffness in the axial direction.

Read MoreCAMX 2020 announces conference program and keynote speaker

Presentations from Microsoft, Uber Elevate, BFG International, Joby Aviation, Anzac Contractors, the Florida DOT will be featured at CAMX 2020.

Read MoreHexcel launches electrically conductive PEKK-based carbon fiber material

HexPEKK EM is a high-performance material for additive manufacturing that meets electromagnetic shielding, radiation absorption requirements.

Read MoreThermoplastic composites add light weight, durability to personal transport

The laptop-sized WALKCAR automatic people mover is constructed from Teijin thermoplastic carbon fiber composite materials.

WatchLanxess launches bio-based prepolymer line Adiprene Green

The bio-based prepolymer line are easy to handle and enable a suitable replacement for existing fossil-based polyether prepolymers.

Read MoreNational Composites Week: Top 20 stories in the last decade

As we celebrate National Composites Week, we’ve collected our top content over the last ten years.

Read More