Resins

Barrier coats in pool production

Barrier coats protect fiberglass swimming pools from invasive water-treatment chemicals.

Read MoreAutomating swimming pool production

Small producer ramps up productivity with "entry level" robotics.

Read MoreFiberglass façade: GRP shapes modernize hotel in Spain

The exterior of the Vista Riviera hotel in Benidorm, Spain, has been transformed with a modern twist, thanks to the fiberglass expertise of Miraplas SL (Monforte del Cid, Spain).

Read MoreTooling for composites: Evolutionary trajectory

New technologies and improved methods keep up as tools get bigger and more complex and toolmaking gets ever more challenging.

Read MoreHigh-speed press cure for high-speed racers

Trapped tooling and compression molding bring cocuring efficiencies to previously autoclave-cured, aerodynamic fins and planes.

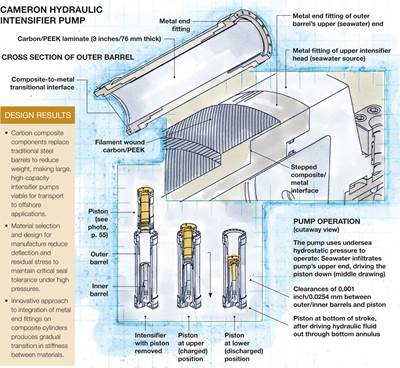

Read MoreCarbon fiber/PEEK takes hydraulic pump to new depths

A switch from metal to composites reduces weight, minimizes part deflection in ultradeep ocean installations.

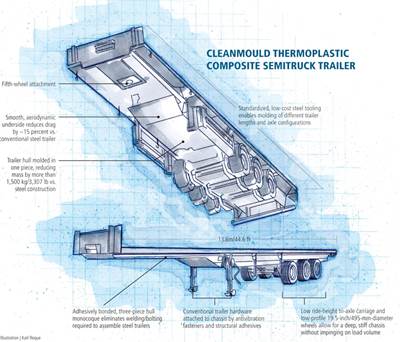

Read MoreThermoplastic composites: Sustainable transport

Cyclic PBT oligomers used to mold Class 8 semitrailer bed via vacuum-bag processing.

Read MoreTough resins for aggressive environments

New thermoset systems drive composites deeper into markets where fire, corrosion, stress and fatigue are ever-present threats.

Read MoreA new "tunable" polyurethane could revolutionize composites

A novel polyurethane-based resin system with tailorable pot life and cure, from Huntsman Polyurethanes (Auburn Hills, Mich. and Everberg, Belgium) now permits composites manufacturers to tailor resin pot life and onset of cure to fit the processing requirements.

Read MoreThermoplastic composites: Primary structure?

Yes, advanced forms are in development, but has the technology progressed enough to make the business case?

Read More