Processes

Orbital Composites, ORNL collaborate to advance robotic polymer and composite AM

The research will focus on the development of a commercially-ready system capable of robotic overprinting on pre-manufactured non-planar surfaces, with multi-material polymers and continuous fiber.

Read MoreCRP Technology produces composite sensor housing box

Commissioned by IMAL s.r.l., CRP applied its carbon fiber-reinforced Windform XT 2.0 material, which retains an 8% increase in tensile strength and 22% increase in tensile modulus.

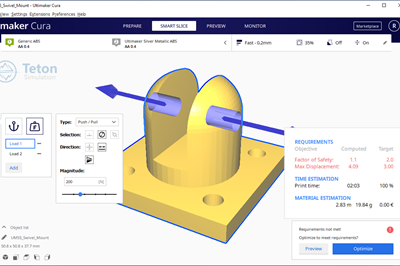

Read MoreTeton launches Smart Slice simulation 3D printing tool

The software automatically optimizes slicing parameters for 3D printers, reduces print iterations and provides near instant feedback on the viability of a user’s project.

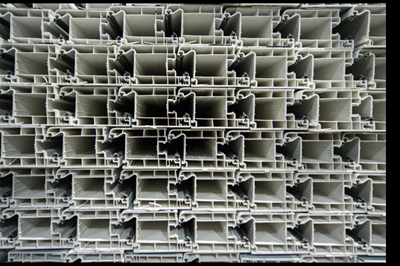

Read MoreAvient debuts improved adhesive resin formulations for thermoset pultrusions

The Glasforms resin formulation cuts down on time, labor and simplifies the manufacturing process for thermoset pultrusions.

Read MoreBBG presents self-closing HP-RTM molds for CFRP compact hydrogen tank production

The autonomous concept, sufficient for series production, enables lower investment costs. Up to 15 cylinders can be produced simultaneously per operation.

Read MoreCall for abstract submissions for 2021 Pultrusion Conference

ACMA and EPTA encourages abstract applications for its 2021 conference from companies of all sizes. The submission deadline is October 23, 2020.

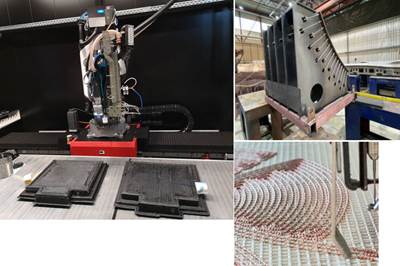

Read More3D printing CFRP molds for RTM flaperon, exoskeletons and more

The Chair of Carbon Composites at TU Munich is advancing composite additive manufacturing via large-scale extrusion, continuous fiber printing, integrating heating into tools and more.

Read MoreAddcomposites and Effman partner to provide AFP cells for SMEs

Aim is affordable, enclosed composites manufacturing cells for many different processes (AFP, grinding, buffing, sanding, drilling) in North American market.

WatchResearchers introduce capillary-driven method for continuous fiber 3D printing

The LITA 3D printing system from the University of Delaware shows potential for in situ cure for high-performance carbon fiber composite parts.

Read MoreComposite Bonding & Repair Benefits and Solutions

Film and paste adhesives, wet peel-ply and potting compounds enable the aviation industry to utilize advanced materials that contribute to lightweighting, more efficient designs, and improved sustainability.

Watch