PEKK

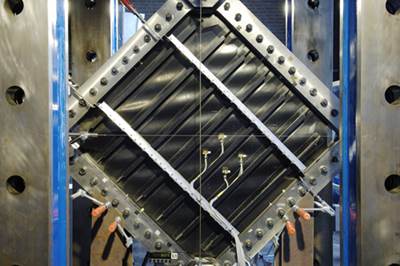

Reinforced thermoplastics in aircraft primary structure

Carbon/PEKK floor beams prove production worthiness of lower cost, fast coconsolidation process.

Read MoreJEC Paris 2011 highlights

The news from this annual Parisian in-gathering of composites professionals is heavily weighted toward automotive lightweighting.

Read MoreCarbon fiber: Program news

In addition to the prognostications of carbon fiber industry watchers, attendees at Carbon Fiber 2010 (Dec. 7-9 in La Jolla, Calif.) also heard news of carbon fiber inroads to a number of composites programs.

Read MoreHigh-Performance Resins 2010 Highlights

Inaugural conference for the advanced resins research crowd updates formulators and processors on the latest developments.

Read MoreAerospace-grade compression molding

Continuous Compression Molding process produces structures 30 percent lighter than aluminum at costs that have both Airbus and Boeing sold.

Read MoreJEC Composites 2009 showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.

Read MoreThermoplastic composites: Inside story

Reinforced thermoplastics buy their way into structural aircraft interior components.

Read MoreAdvanced materials for aircraft interiors

Applications aren't as demanding as airframe composites, but requirements are still exacting — passenger safety is key.

Read MoreThermoformable Composite Panels, Part II

Preconsolidated sheet stock for load-bearing applications features continuous fiber - not only glass, but carbon and aramid as well.

Read MoreThermoformable Composite Panels, Part 1

Preconsolidated fiber-reinforced thermoplastics offer short cycle times, tailored properties, recyclability and lower cost.

Read More