Out of Autoclave

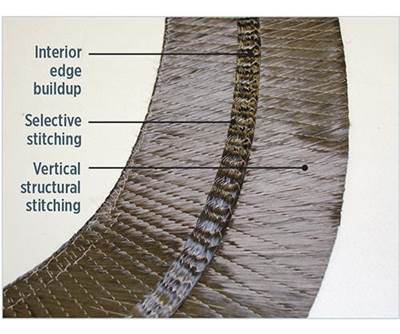

Can basalt fiber bridge the gap between glass and carbon?

When I started writing about composites in the way, way back, industry innovator Brandt Goldsworthy was still alive. His article on basalt fiber was one of the most-read columns in the old Composites Technology book, and there seems to be a lot of interest in this alternative performance fiber. Mafic SA is a new player in the basalt fiber market.

Read MoreCarbures: Conquering the world for composites

This global Tier 2 supplier produced 39,322 parts for Airbus in 2015, has sold seven RMCP machines to China capable of 40,000-75,000 composite auto parts/yr and is completing a study on opportunities for composites in oil and gas applications in Mexico. What next?

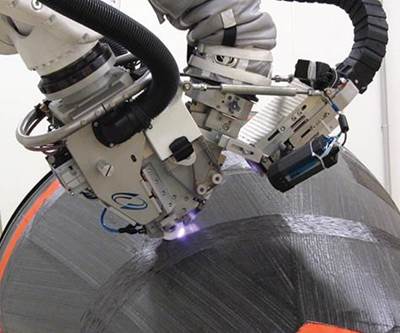

WatchAutomated dry fiber placement: A growing trend

Many collaboratives and individual companies have pursued or are currently pursuing initiatives in dry fiber placement and OOA process development.

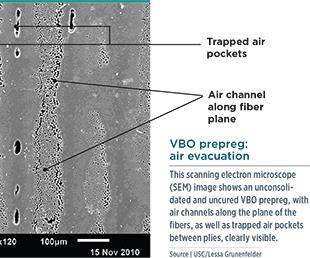

Read MoreVBO prepreg on wing structure

GE Aviation scores first use of OOA wing trailing edge on large commercial aircraft.

Read MoreResearch on OOA processing continues

Much work has been done to make OOA processing practical for aerospace applications, but much work still remains if it is to become the compelling option.

Read MoreDry fiber placement: Surpassing limits

Coriolis Composites’ automated aerostructures manufacturing using dry materials moves from development projects to production.

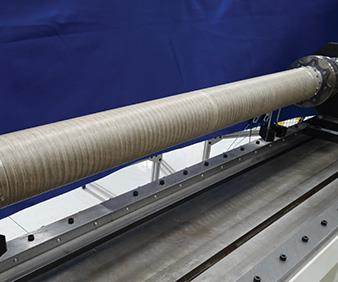

Read MoreOOA: Thermoplastic alternative targets performance spec

CF/PEEK helicopter driveshaft’s toughness trumps traditional metric.

Read MoreVBO prepregs: The Vision SF50

OOA vacuum-bag-only process makes carbon fiber structures a reality for the world’s first personal jet.

Read MoreResin transfer molding: An update

Fulfilling the promise of OOA composites without sacrificing pressure.

Read MoreResin infusion: Taking off?

Boeing Aerostructures Australia leads large-scale development of resin infusion as an industrial process.

Read More