Materials

CAMX 2020 exhibit preview: AGC Chemicals

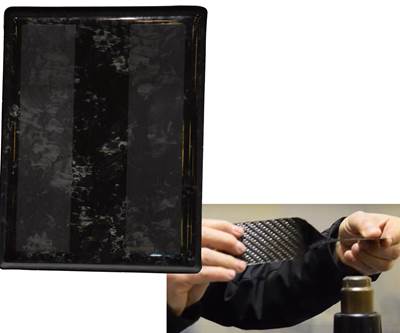

AGC Chemicals Americas' mPLASTICS are new fluoropolymer-modified compounds to enhance the performance of carbon fiber-reinforced thermoplastic composites.

Read More3D printed FRP footbridge paves way for circular composites

The thermoplastic composite footbridge incorporates a short glass fiber-filled PET specifically designed for 3D printing.

Read MoreRock West Composites announces Quaranvent design competition winner

Winner Craig Monroe devised a 15-foot inflatable kayak that weighed only 12 pounds, and incorporated carbon fiber components.

Read MoreThe industrialization of thermoplastic epoxy

Fast-processing composites that are strong yet tough, thermoformable, reformable, recyclable and even FST-compliant save cost in aircraft and rail equipment.

Read MoreGerman Bionic unveils fourth-generation carbon fiber exoskeleton

The Cray X features a frame made with SGL Carbon carbon fiber and aids workers when lifting loads of up to 28 kilograms for up to eight hours.

Read MoreCAMX 2020 Preview

Transformed into a virtual event, the latest CAMX 2020 preview describes some of the opportunities that will be available for visitors and exhibitors.

Read MoreHartzell carbon fiber propellers chosen as option for Cubcrafter aircraft

The three-blade Pathfinder propeller, weighing in at 44 pounds, is an alternative to Hartzell’s two-blade carbon fiber Trailblazer prop.

Read MoreElectroimpact’s 6-axis continuous fiber 3D printer, one part of future multi-functional manufacturing cell

The Scalable Composite Robotic Additive Manufacturing (SCRAM) system 3D prints with continuous fiber tape or filament and seamlessly swaps end effectors for large-scale pellet deposition and CNC machining.

WatchSky Advanced Materials fabrics win DNV-GL type approval

Certification for Hungary-based Sky Advanced Materials covers use of fabrics made with Zoltek PX35 50k tow carbon fiber combined with epoxy or vinyl ester.

Read MoreSino Polymer develops high-performance epoxy resin prepreg

Used in railway applications, the carbon fiber prepreg can be cured at 150℃ for 10 minutes, and is suitable for structural parts requiring Tg within 120-140℃.

Read More