Fabrics/Preforms

Hot drape forming

Heat, vacuum and/or pressure advance from debulking prepreg layups to automated preforming of dry reinforcements for faster composites production.

Read MoreSpintech opens new composites manufacturing division, Hawthorn Composites

New division specializes in manufacturing complex geometry composite parts using novel dry fiber preforming and resin infusion techniques, extending Spintech composite capabilities.

Read MorePilatus delivers 100th composites-intensive jet

PC-24 Super Versatile Jet is now present on every continent and sold out for 2021.

Read MoreFlexible carbon fiber plates enable high-performance footwear

Carbitex’s flexible carbon fiber/thermoplastic composite plates use creative engineering to eliminate design compromises in athletic footwear.

WatchHexcel, Safran expand contract for composite materials in commercial aerospace programs

Long-term supplier contract amended to include Hexcel’s HexTow IM7 for the GE9X engine, as well as core, adhesives, prepregs and fabrics for additional aerospace applications.

Read MoreCevotec SAMBA Pro Prepreg system added to FPC technology portfolio

Installation of the automated Fiber Patch Placement system in Fraunhofer IGCV’s Fiber Placement Center serves active technology and application development.

Read MoreHypetex, SHD offer colored carbon fiber prepreg solutions

The partnership will supply Hypetex-colored fabrics with SHD’s MTC500 series epoxy resin systems, enabling visual component finishes and the potential for weight and cost savings.

Read MoreBraided preforms meet phase-change tooling

A program from the U.S. Air Force Research Laboratory adopts automated braiding and phase-change tooling for a complex geometry unmanned aircraft part.

WatchUpdate: Lower wing skin, Wing of Tomorrow

Airbus is evaluating several advanced composites technologies as part of its Wing of Tomorrow program. Among these is liquid resin infusion of the lower wing skin, being developed by Spirit AeroSystems.

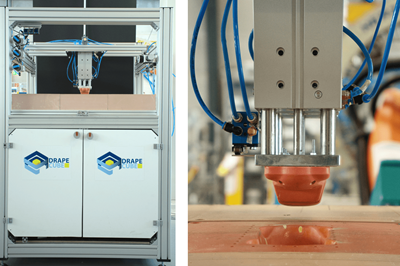

WatchDrapeCube offers cost-effective preforming process for FRP textile production

The DrapeCube offers a cost-effective design for the production of fiber preforms from textile semi-finished products.

Read More