Epoxies

ATL Composites contributes to concrete pillar remediation project

Six new support pillars incorporate Hexcel ZU300 UD carbon fiber and ATL’s Technirez R2517 epoxy resin with H2431 slow hardener that will protect against storm water issues.

Read MoreNext-generation composites materials and processes explored

A supplement with the November 2020 issue of ÂÌñÏ×ÆÞ takes a close look at some of the technologies that are driving innovation in the composites industry.

Read MoreKisling epoxy adhesive improves carbon fiber bonding performance in automotive applications

The 2K-Epoxy ergo 7440 offers the removal of the bond-line read-through, attain high temperature resistance, avoids contact corrosion and enables quick turnaround during production.

Read MoreReprocessable thermosets and thermoplastic epoxies: An expanding landscape

New chemistries give thermosets new thermoplastic-like versatility.

Read MoreEpisode 34: Carmelo Lo Faro, Solvay Composite Materials

Carmelo Lo Faro, president of Solvay Composite Materials, talks about how he sees aerocomposites evolving in the time of COVID-19, the rise of computational power to evolve composites use, the prospects for increased composites use in the automotive market, and the increasing importance of education in the composites industry.

ListenHexcel third quarter financials reflect industry headwinds

Slowdown in commercial aerospace and the wind energy market has decreased Hexcel’s year-to-date sales by 32.6%. The company will close its wind energy glass fiber prepreg line in Windsor, Colo., U.S., in early November.

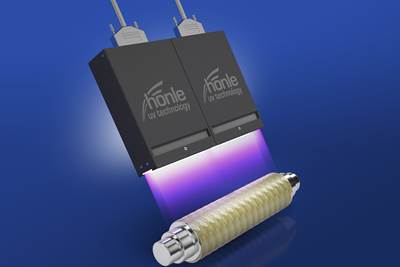

Read MoreTechsil, Panacol offer Vitralit adhesive for filament winding

The transparent one-component epoxy adhesive and curing system is ideal for carbon fiber or glass fiber filament winding.

Read MoreAutomated aerocomposites production: Liquid molding or welded thermoplastic?

Two materials and process approaches are demonstrated for CFRP bulkhead production.

Read MoreComposite aerostructures in the emerging urban air mobility market

In the not too distant future, point-to-point, limited-distance, piloted and autonomous air travel for people and cargo will be the norm. Composites will make it possible.

Read MoreBuilding the Museum of the Future

FR composite panels provide structure, sealing and iconic facade for pioneering architecture in Dubai.

Read More