Sino Polymer develops high-performance epoxy resin systems for prepreg applications

The one-component carbon fiber prepreg can be cured at 150ºC for 10 minutes, is suitable for structural parts requiring Tg within 120-140ºC and can be stored for up to 18 months at -18ºC

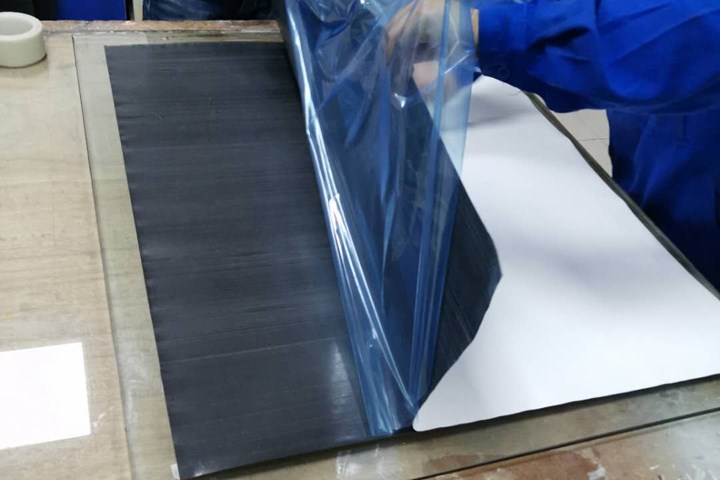

HL3 carbon fiber epoxy prepreg for railway applications. Source | Sino Polymer

Originally focused on aerospace applications, (Shanghai, China), has recently developed high-performance epoxy resin systems, including a one-component flame-retardant epoxy resin system for carbon fiber prepreg, that can be used in railway applications. The system is said to be halogen-free, and exhibits low smoke density/toxicity properties and a long shelf life.

Using this one-component epoxy resin system, Sino Polymer says, its carbon fiber (T-300) prepreg has recently passed the EU EN45545-2 R1 fire safety standard test and reached HL3, the highest flame-retardant level. Further, the company notes the prepreg can be cured at 150ºC for 10 minutes, is suitable for structural parts requiring Tg within 120-140ºC, retains a shelf life at room temperature (60 days at 21-23ºC) and can be stored for up to 18 months at -18ºC. Further, the company notes the system can be used in various processes, including infusion, pultrusion, hand layup and filament winding.

Sino Polymer has also developed systems for wind energy and marine applications, including two room temperature, fast-curing two-component epoxy resins to infuse with fiberglass for fabricating FRP wind turbine parts and boats, which can be cured in 1.5-2 hours, and two-component epoxy resins for carbon fiber wind blade spar caps using a pultrusion process with a speed of less than 0.8 meters per minute, and a 2-millimeter thickness. Other systems are available for carbon fiber gas cylinders and other composite materials with hand layup and filament winding processes.

This post is courtesy of the ÂÌñÏ×ÆÞ and media partnership.

Related Content

-

ASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

-

Filament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

-

Anemoi installs 35-meter-tall composite rotor sails on Sohar Max maritime vessel

Carbon fiber-reinforced epoxy composites are key to building these long-lasting wind propulsion technologies for energy-efficient watercraft.