Digitization

Scaled Composites Model 437 aircraft to be flown for Beacon autonomy testbed

Northrop Grumman subsidiary part of Digital Pathfinder development of stealth aircraft with wings using continuous carbon fiber additive manufacturing and determinate assembly.

WatchPlant tour: Hexagon Purus, Kassel, Germany

Fully automated, Industry 4.0 line for hydrogen pressure vessels advances efficiency and versatility in small footprint for next-gen, sustainable composites production.

Read MoreThe pursuit of energy efficiency in composites manufacturing

In an increasingly energy-driven world, technology developments are being sought after to reduce energy consumption in composites manufacturing, further translating into waste reduction and other efficiencies.

Read MoreSchrödinger advances materials informatics for faster development of next-gen composites

Cutting time to market by multiple orders of magnitude, machine learning and physics-based approaches are combined to open new possibilities for innovations in biomaterials, fire-resistant composites, space applications, hydrogen tanks and more.

Read MoreDigitized material shipment process improves MRAS aerostructures operations

Digital Passport technology by Plataine shortens receiving process to minutes, enhances quality and supply chain collaboration.

Read MoreAerotech Academy Puglia is inaugurated at Leonardo Aerospace site in Grottaglie, Italy

Joining the Leonardo MaTeRIA Lab and Joint Lab with Syensqo, this aerostructures training course will be 75% materials science and structural design/analysis, 25% digital transformation and AI.

Read MoreOn the radar: Composite materials producer ramps up sustainability vision

Toray is one of many companies in the composites industry fostering improvements in recyclability and biocomposites, as exemplified by its latest announcements.

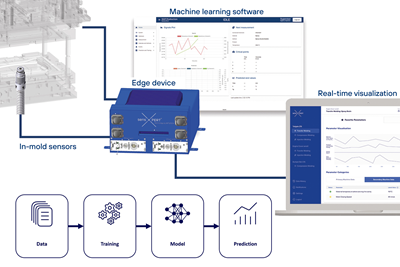

Read MoreNext-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

WatchMachina Labs unveils Machina Deployable System for agile manufacturing

Portable system combines AI and robotics for the forming and cutting of custom composite and metal parts.

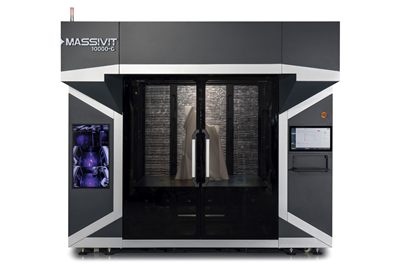

Read MoreLarge-scale additive system prints industrial molds for composites

CAMX 2023: The Massivit 10000-G, with gel dispensed printing offers an ultra-fast, sustainable and cost-effective way to digitize isotropic mold production for high-quality and more reliable composite parts.

Read More