Defense

Parker Hannifin completes acquisition of Meggitt PLC

With the acquisition, Parker Aerospace Group aims to expand its portfolio with Meggitt’s global defense and aerospace technologies.

Read MoreBAE Systems composite mission workstation qualifies to serve aboard P-8A Poseidon

Maritime patrol and reconnaissance aircraft takes to the skies with the reliable mission computing technology which improves aircraft and weapon systems’ performance.

Read MoreCAMX 2022 exhibit preview: Qarbon Aerospace

Qarbon Aerospace exhibits its capabilities in manufacturing composite components and assemblies, highlighting its proficiencies in major assembly and systems integration, automated layup, hand layup, high-temp composites and core fabrication.

Read MoreWeber State opens MARS Center in Utah, creates opportunities for advanced manufacturing

Miller Advanced Research and Solutions (MARS) Center brings together students, faculty, university partners and the community for research and innovation in the aerospace and defense field.

Read MoreLockheed Martin expands development, production of ultra-high temp CMCs with facility expansion

Targeting current and future needs in hypersonic and aeronautics applications, Lockheed Martin Skunk Works’ Allcomp team is increasing and digitizing its capabilities in ceramic matrix composite (CMC) materials and parts fabrication.

Read MoreWickert commissions composite press for ballistic plate production

Wickert reports an increasing interest in complete presses used to produce composites-intensive armor for civilian and military vehicles, ships and aircraft.

Read More2022 Farnborough International Air Show highlights

Farnborough, as usual, provided a platform for a variety of announcements in the aerospace, defense and advanced air mobility spaces from companies like GKN Aerospace, Joby, Airbus, Rolls-Royce, Boom Supersonic and others.

Read MoreTeam Tempest combat air demonstrator set to fly

Plans have been confirmed for the development of the U.K. Tempest demonstrator, a project involving novel technologies R&D for next-gen skills, tools and processes, including composites.

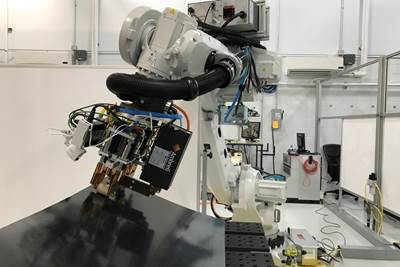

Read MoreHigh-performance, high-detail continuous 3D-printed carbon fiber parts

Since 2014, Mantis Composites has built its customer and R&D capabilities specifically toward design, printing and postprocessing of highly engineered aerospace and defense parts.

Read MorePlant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

Read More