Defense

UMaine Composites Center 3D prints logistics vessel for U.S. Department of Defense

Two 3D-printed vessels capable of transporting two shipping containers and a Marine rifle squad with three days of supplies mark groundbreaking composite manufacturing milestone.

Read MoreSikorsky extends Kaman Aerospace cockpit deal for the HH-60W helicopter

Kaman’s work will include final assembly of the cockpits, detail metal part manufacturing and procurement of composite parts, in addition to other associated components.

Read MoreAir Force awards $100 million to continue WSU NIAR’s B-1 Digital Engineering program

NIAR’s continued support of adapting the composite warfighter through digital manufacturing will reduce cost, expanding the supply base and increasing aircraft mission readiness.

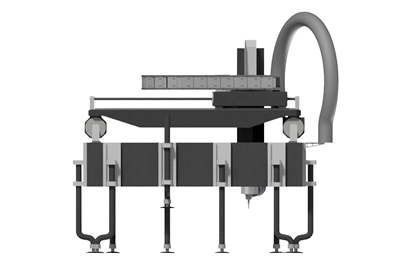

Read MoreLifting arm concept and automated repair training to propel portable repair system

Looking to commercialize its Portable Scarfing/Composite Repair System concept, AGFM and partners offer specialized training, lifting and inspection systems.

Read MoreReactivated Israel Aerospace Industries production line resumes F-16 wing deliveries

With the 1980s assembly line fully reopened and refurbished, IAI continues production of the military aircraft’s wings and composite vertical fin.

Read MoreAnduril Industries acquires AUV startup Dive Technologies

Dive builds autonomous underwater systems using large-format additive manufacturing and composite materials for commerial and defense-based undersea exploration.

Read MoreAlbany Engineered Composites wins ten-year contract for CH-53K helicopter assemblies

Selected by Lockheed-Sikorsky, AEC will leverage its composites expertise in engine and airframe applications to meet a 2023 delivery period.

Read MoreLockheed Martin terminates agreement to acquire Aerojet Rocketdyne amid regulatory roadblocks

The U.S. Federal Trade Commission blocked the aerospace, arms and defense corporation over antitrust concerns in January.

Read MoreKaman Composites expands Part 145 capabilities to ATR, ERJ composite repairs

FAA-approved expansion for repair station in Wichita, Kansas, now includes services for the commercial aftermarket.

Read MoreLockheed Martin's LMXT strategic tanker aircraft will be made in Alabama and Georgia

The LMXT is produced as a composites-intensive A330 airliner at Airbus’ Mobile, Alabama, facility and converted into tanker role at Lockheed’s facility in Marietta, Georgia.

Read More