Pinette Emidecau Industries

Pinette

5 rue Paul Sabatier, BP 80077

Chalon Sur Saone, 71103 FR

33 385 478 800

pei@pinetteemidecau.com

About Pinette Emidecau Industries

IS THIS YOUR COMPANY?

As Seen On ÂÌñÏ×ÆÞ

Pinette Emidecau Industries Supplies the Following Products

- Chillers

- Coaters

- Compression Molding

- Diaphragm Forming

- Hydraulic

- Laminating

- Low-Pressure

- Metal (aluminum, invar, nickel shell, steel)

- Other Primary Manufacturing Equipment

- Ovens, General

- Preform Manufacturing Equipment

- Resin Transfer Molding Equipment (RTM)

- Robots

- RTM/Resin Infusion

- Software & Controls

- Superplastic Forming

- Thermoforming/Pressure Forming

- Vacuum

- Vacuum-Assisted Resin Transfer Molding Equipment (VARTM)

Editorial, News, and Products

-

KVE, Pinette PEI to supply TPC induction welding equipment

Integrated solution for TPC stamp forming and part assembly via induction welding opens capabilities for increased part sizes, reduced weight and production cost, optimized cycle times.

-

What you might have missed at Paris Air Show 2025

A surge in defense spending, partnerships in hydrogen propulsion and new combat aircraft agreements, many backed by composites industry leaders, culminated the 55th Paris Air Show.

-

Composites end markets: Aviation and advanced air mobility (2025)

Despite persistent supply chain issues, markets were set for healthy growth before Trump policies and tariffs, yet long-term trends favor composites in new platforms. Meanwhile, advanced air mobility shakes out and moves forward.

-

French players form Composites TP Team for TPC advancement

This five-member team strives to support manufacturers of all sectors in the move toward thermoplastic composites (TPC), enabling them to benefit from a single point of access to comprehensive and integrated services.

-

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

-

VIDEO: Installing the world’s largest thermoplastic composites press at Airbus Bremen

At JEC World 2025, Pinette PEI detailed its latest turnkey system for future aircraft serial parts production.

-

Pinette commissions large-scale stamp-forming press for TPCs

Airbus Aerostructures facilities will integrate this forming press that is expected to advance next-gen aerospace parts production thanks to its size and performance.

-

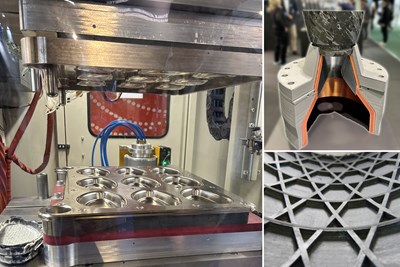

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

-

CW presents "CW Tech Days: Thermoplastics for large structures"

Attend this May 18th interactive webinar sponsored by Altair, Mitsubishi Chemical Group, Toray and Collins Aerospace which will explore the materials and processing technologies that are enabling the transition into thermoplastics.

-

High-rate, automated aerospace RTM line delivers next-gen spoilers

At Spirit AeroSystem’s Prestwick facility in Scotland, a glimpse of the future of aerocomposites manufacturing in a resin transfer molding line for A320 spoilers.

-

Consortium targets solutions for carbon fiber thermoplastic composite structures

The HAICoPAS project, led by Hexcel and Arkema, aims to optimize UD tape design and manufacture for aerospace and automotive composites.

-

Institut de Soudure Groupe optimizes production control for large-sized composite parts

Partnership with aerostructures supplier Duqueine installs thermography to reduce inspection time and cost.

-

FastRTM project demonstrates manufacturing of complex, net-shape composite parts

Automated production platform developed by a French industry consortium utilizes an epoxy resin system from Hexion Inc.

-

Automated Preforming, Part 3: Quilted Stratum Process

CW’s tour of Cetim and the QSP line which preforms multi-thickness thermoplastic materials in 40-90 seconds for composite parts with cycle times of 1-2 minutes.

-

Preforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

-

JEC 2017 – Aiming for Industrialization

The exhibit floor in Paris reflected composites’ move toward high-rate and high-volume production.

-

JEC World 2016, the full report

ÂÌñÏ×ÆÞ's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

-

Turnkey manufacturing systems: Part-per-minute thermoplastic composites

Pinette Emidecau Industries’ (PEI, Chalon-sur-Saône, France) leads a consortium of providers that are collaborating on the Quilted Stratum Process (QSP), a means to accelerate thermoplastic composites processing in the auto industry.

-

Turnkey manufacturing systems: Materials, markets and maturation

Automated production cells promise affordability and less risk in scaling up composites production, but are they really the path forward?

-

Plant Tour: Fokker Aerostructures: Hoogeveen, Netherlands

This Dutch aerospace supplier leverages its founder’s pioneering spirit from a century ago to lead the way, today, in thermoplastic aerocomposites.

-

Automation and rapid processing dominate at JEC Americas

Highlights include Fiber Patch Preforming, automated potting and insert equipment and processes delivering composite parts in minutes.

-

Thermoplastic composites technology: A view from Europe

For this Dutch consortium, bringing the manufacturability of thermoplastic materials to maturity is the goal in concert with OEMs, materials and equipment supplier members.

-

2014 JEC Europe Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

JEC Europe 2014 Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

Business and busy-ness

CT editor-in-chief Jeff Sloan returns for JEC Europe 2014 in Paris with observations about several intriguing composites industry trends.

-

Albany Engineered Composites: Weaving the Future in 3-D

This 3-D weaver turned composite component supplier pursues a future in 3-D structures through continuous technology development.

-

Inside a thermoplastic composites hotbed

As production of the A350 XWB ramps up, so does manufacture of the thermoplastic fuselage clips the plane requires. HPC sees how it’s done.

-

Main landing gear doors designed for all contingencies

For the Airbus XWB airliner, they must meet strict structural, aerodynamic, emergency and aesthetic requirements.

-

High-speed RTM work cell holds promise for faster part production

Pinette Emidecau Inc. (Troy, Mich.) reports that it has developed an automated, high-speed RTM cell for aerospace and automotive manufacturing applications that is designed to increase molded part throughput and improve process consistency.