ANSYS, Inc.

2600 Ansys Dr.

Southpointe

Canonsburg, PA 15317 US

844 462 6797 | 844 Go Ansys

ansysinfo@ansys.com

CONNECT

About ANSYS, Inc.

Using engineering simulation software, our customers can rapidly innovate and easily validate design ideas, predicting the future of transformational products.

IS THIS YOUR COMPANY?

As Seen On ÂÌñÏ×ÆÞ

ANSYS, Inc. Supplies the Following Products

- CAE (Computer Aided Engineering)

- Cae Design

- Finite Element Modeling/Analysis (FEM/FEA)

- Modeling/Simulation/Virtual Testing Software

- Mold Flow & Simulation Software

- Product & Tool Design, Analysis Software (CAD/CAM/CAE)

Editorial, News, and Products

-

Ansys launches 2025 R2 with enhanced simulation, accessibility and AI

Ansys 2025 R2 amplifies human ingenuity with AI-driven tools and features that simplify simulation adoption, encourage collaboration and boost productivity across teams.

-

CIRA qualifies CMC structures for the reusable Space Rider

Italian team designs, builds and tests multiple large, complex thermal protection system structures made from patented ISiComp C/C-SiC ceramic matrix composites.

-

Design for manufacturing, assembly and automation enables complex CFRP telescope supports

Airborne delivered two mirror support structures for the FYST and SOLAT telescopes, assembling 26,300 components while maintaining near-zero CTE, strict tolerances on 6.5 × 6.5 × 1.8-meter assemblies.

-

Reinforcing hollow, 3D printed parts with continuous fiber composites

Spanish startup Reinforce3D’s continuous fiber injection process (CFIP) involves injection of fibers and liquid resin into hollow parts made from any material. Potential applications include sporting goods, aerospace and automotive components, and more.

-

Next-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

-

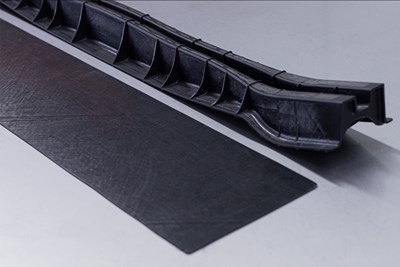

Optimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

-

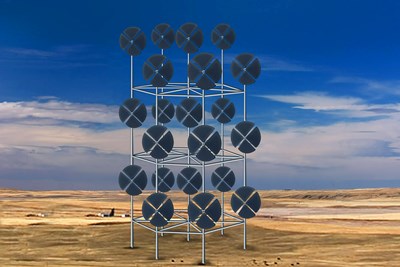

Drag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

-

Demonstrating functionalized, cost-effective composites using additive extrusion

Hybrid thermoset/thermoplastic composite part with 3D-printed functionalization demonstrates technology possibilities and EmpowerAX open platform offering expertise from members throughout the process chain.

-

CFRTP upper stage propellant tank

PROCOMP uses in-situ consolidation AFP and ultrasonic welding to demonstrate lightweight, novel tank design.

-

One-shot manufacture of 3D knitted hybrid thermoplastic composite structures

MAPICC 3D project replaces steel seat support in heavy-duty vehicle with a 3D knitted composite made from thermoplastic hybrid yarns comprising the matrix and reinforcing components.

-

Plant tour: Dowty Propellers, Gloucester, U.K.

Transforming decades of design and RTM production reliability into more sustainable, next-generation composite propellers.

-

Modernizing the mechanical rotor sail

Composites are key for Norsepower’s award-winning redesign of a century-old rotor sail for reducing carbon emissions on passenger and cargo ships.

-

Improving analyses of composite pressure vessels

Accurate geometry modeling and equivalent material property approximations captured by WoundSim will play a role in improving COPV analyses.

-

Safran Aircraft Engines selects Ansys software to support CFM RISE engine

Safran Aircraft Engines will employ Ansys’ FEA simulation solutions to address an advanced, open fan architecture, higher temperature composites and hybrid electrification.

-

Multi-composite thrust chamber aims to boost rockets, reduce cost for New Space economy

Black Engine uses new, microporous CMC liner for transpiration cooling and multiple lightweight composites in modular design that offers increased lifetime and lower maintenance versus current launch vehicle engines.

-

Industrial-scale wave energy system enabled by mobile filament winding

Sweden-based CorPower Ocean designed its 9-meter-long, filament-wound GFRP buoy prototype for high-efficiency, durable wave energy generation and fast, on-site manufacture.

-

Using machine learning to accelerate composites processing simulation

A speed gain of 1,000 to 10,000 times greater than traditional FE models has been achieved using machine learning models, enabling near real-time simulation for large composite components.

-

Speeding RTM with heat-flux sensors

Clean Sky 2 INNOTOOL 4.0 project advances cure monitoring for larger and less costly lightweight landing gear made using composites.

-

Optimizing a wind turbine nacelle cover to meet LCOE demand

Suzlon Group redesigned a composite nacelle cover with in-situ molded stiffeners to reduce manufacturing and material costs while maximizing part performance.

-

Glass fiber and phenolic prove their mettle in camshaft module

Replacing aluminum, a fiberglass/phenolic module reduces mass and NVH in a prototype structure and speeds assembly line installation.

-

The Alpha launch vehicle: Designing performance in, cost out

Firefly Aerospace’s Alpha 2.0 launch vehicle, designed to deliver satellites into low Earth orbit, gets a composites makeover in pursuit of larger payload capacity and more cost-effective performance.

-

TU Munich gears up for full-scale Hyperloop demonstrator

As a new, university-directed research program, the Technical University of Munich Hyperloop team works to scale up its SpaceX competition-winning pod design.

-

9T Labs, ANSYS partner on composite design and simulation tools

A combination of software provides an integrated design and simulation workflow for 3D printing complex composite parts.

-

A clean technology for clean, zero-emissions buses

Monocoque composite body designed to support all bus loads.

-

MultiMech 18.0 features improved accuracy and speed

MultiMech 18.0 empowers engineers to perform faster, smarter and more realistic analysis of composites.

-

Consolidating thermoplastic composite aerostructures in place, Part 1

After more than 30 years of development, in-situ consolidation is nearing its promise to eliminate fasteners and the autoclave, and enable an integrated, multifunctional airframe.

-

Converting the structural chassis to composites

Germany’s largest producer of GRP leaf springs for cars and trucks broadens its product range to CFRP stabilizer bars, which cut weight 50% vs. steel.

-

Software Update: Simulation saves

A look inside the increasingly well-equipped virtual toolbox for composite design, analysis, and manufacturing.

-

Tailored Fiber Placement: Besting metal in volume production

Affordable automated production of highly optimized preforms and parts.

-

Designing for high pressure: Large-diameter underground pipe

Careful analysis is needed to ensure success of buried composite piping for industrial applications.

-

Carrier-capable, all-composite external fuel tank

Legacy product positions builder for a shot at an F-35 contract.

-

Digital design, RTM update aircraft propeller

Second-generation type-certified propeller delivers for Cirrus Aircraft’s SR-22 at a more affordable price.

-

Metal-matrix composites used to lighten military brake drums

Century Inc.'s combination metal-matrix composite (MMC)/aluminum brake drum is a lightweight alternative to cast iron and steel brake drums in military vehicles.

-

Residential construction breakthrough: Composites find a home

Composite materials get the go-ahead for an unconventional but code-compliant California house.

-

FEA facilitates custom megayacht design

Modeling software and design ingenuity meet vibration challenges in ocean-going luxury yacht.Â

-

Regional buses boost CFRP in alternative energy

Diesel-to-fuel-cell bus conversions signal potential niche for composites in public transit powertrains.

-

Team-built bus body bests all

OEM meets tight development schedule on superlight multipart molded shell to offset propulsion system weight in fuel cell-powered transit bus.

-

Pultruding cost out of aerospace parts

Design-for-manufacturing effort proves to be cost-effective for carbon/epoxy airfoil on expendable UAV.

-

Composites the right choice for subsea ocean observatory

Pultruded structure provides durable platform for Deep-ocean Environmental Long-term Observatory System (DELOS) project’s groundbreaking marine study.

-

SMC Flexes Muscles in Other Markets

Often identified with automotive body applications, sheet molding compound shows growing promise in a variety of other temperature- and weather-resistant applications.

-

FEA Roundup: Design, Simulation And Analysis Converge

New modeling and analysis software products increase the accessibility and reliability of finite element analysis data.

-

The ABCs of FEA

Computerized and adapted for composites, finite element analysis reduces R&D expense and shortens time to market.

-

Anisotropic wind blade design expected to reduce wind-energy costs

Deliberately unbalanced laminate produces smoother power input from adaptive wind blades

-

Vinyl ester composite parts in boat stern drive resist corrosion and damage

Volvo Penta's Ocean Series brings vinyl ester composites to the powertrain end of the boat.

-

Fighting Ships Augment Combat Readiness With Advanced Composites

Navies adopt composite materials for stealth and speed.