Safran Aircraft Engines selects Ansys software to support CFM RISE engine

Safran Aircraft Engines will employ Ansys’ FEA simulation solutions to address an advanced, open fan architecture, higher temperature composites and hybrid electrification.

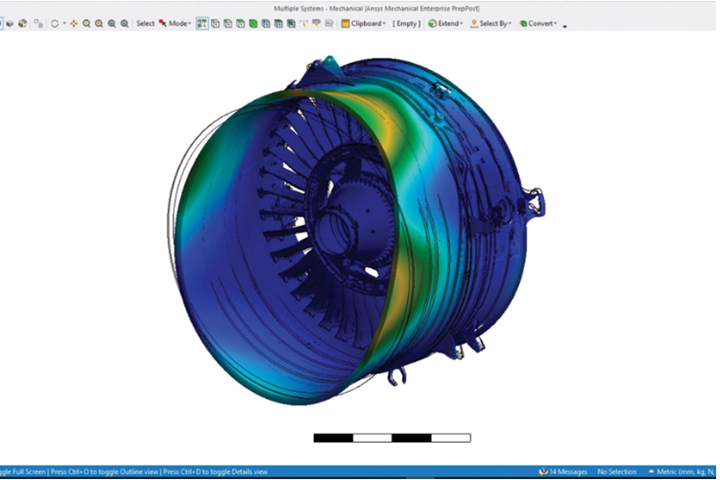

Static structural analysis of an Intermediate Compressor Frame in Ansys Mechanical. Photo Credit: Ansys

Aircraft engine manufacturer (Courcouronnes, France) will implement Ansys’ (Canonsburg, Pa., U.S.) finite element analysis (FEA) tools as an end-to-end structural and thermal simulation solution in new programs for developing next-generation aircraft engines. The integration will support aviation sustainability efforts while advancing Safran Aircraft Engine’s productivity and cost efficiency.

Safran Aircraft Engines will deploy FEA software for design and validation in the CFM RISE technology program, which is driven by the global aviation industry commitment to achieve net-zero carbon emissions by 2050 and is targeting composites, additive manufacturing (AM) and hybrid-electric. Simulation is said to be an important technology to accelerate the development of novel, sustainable-by-default technologies, while also upgrading existing technologies to meet energy-efficiency standards.

As such, the RISE program will leverage Ansys’ robust simulation tools to support three main technology pillars, including sophisticated structural designs such as an open unducted fan, upgraded composite materials to combat higher temperatures and hybrid electrification to enable the reduction of fuel consumption and CO2 emissions by more than 20% compared to today’s most efficient engines. Additionally, high-fidelity solver features such as fluid-structure interaction capabilities and faster solve times will reportedly allow Safran Aircraft Engines to slash development time with a significant reduction in simulation workflow compared to the company’s previous FEA tools.

“Ansys’ best-in-class simulation software and deep understanding of the challenges of our industry will enable us to support our engineers to develop sustainable technologies for our future aircraft engine programs,” Michel Brioude, vice president of engineering, research and technology at Safran Aircraft Engines, says. “By leveraging Ansys’ tools, Safran Aircraft Engines will benefit from improved usability, a streamlined workflow and a set of technologies that enables scalability and optimizes our research and development process through virtual prototyping.”

Ansys will offer technical support to Safran Aircraft Engines as they integrate the software in current and future developments

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

-

Plant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.