Aligned Vision

27 Industrial Ave.

Chelmsford, MA 01824 US

978-244-1166

sales@aligned-vision.com

CONNECT

About Aligned Vision

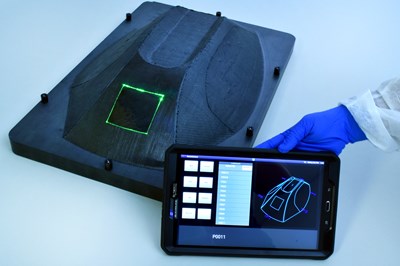

Best-in-class automated guidance and inspection solutions. Laser templating features independent, full-function graphic remote control for each operator. Automatic inspection offers real-time FOD prevention; detection of out-of-tolerance features; electronic documentation; and Industry 4.0 gateway.

IS THIS YOUR COMPANY?

As Seen On ÂÌñÏ×ÆÞ

Aligned Vision Supplies the Following Products

- Composites Materials Handling

- Inspection Services

- Kitting Equipment & Software

- Process Controls

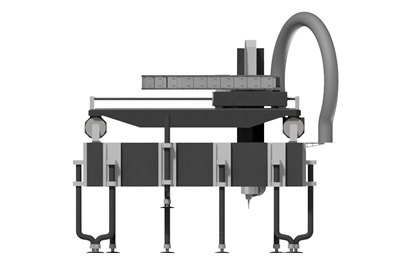

- Projection/Alignment Systems, Laser

- Repair Kits & Equipment

- Surface Analyzers

Trade Names Offered by Aligned Vision

Editorial, News, and Products

-

Plant tour: Qarbon Aerospace, Milledgeville, Ga. and Red Oak, Texas

Veteran aerostructures Tier 1 transforms into 21st century leader in thermoplastic composites and multiple new markets.

-

Lifting arm concept and automated repair training to propel portable repair system

Looking to commercialize its Portable Scarfing/Composite Repair System concept, AGFM and partners offer specialized training, lifting and inspection systems.

-

Aligned Vision brings CAD-like user interface to composites

A key feature of Align 4.0 is its CAD-like user interface, which the company claims is the only data-delivery and data-collection system for composite layup operators to use at the tool.

-

IACMI Members Meeting reconnects members, discusses road ahead

Oct. 5-7 in Detroit, Institute for Advanced Composites Manufacturing Innovation (IACMI) members presented automotive R&D and discussed industry trends.

-

Hot drape forming

Heat, vacuum and/or pressure advance from debulking prepreg layups to automated preforming of dry reinforcements for faster composites production.

-

Valuable data: From travelers to the as-built digital twin

Taking advantage of the electronic record proves to be of significant value to composite fabricator’s record-keeping process.

-

Kanfit installs new autoclave, automated cutter to increase composite parts production capacity

Composite parts producer in Israel increases capabilities for composites, 3D printing and hybrid assemblies.

-

Composites suppliers, fabricators respond to coronavirus

Companies across the composites industry supply chain share how the COVID-19 pandemic is affecting their businesses, and how they are available to help.

-

SME recognizes leaders in aerospace and defense manufacturing

Boeing technical fellow Kurtis Willden, Aligned Vision and the Boeing Co. received 2020 Excellence in Composites Manufacturing Awards.

-

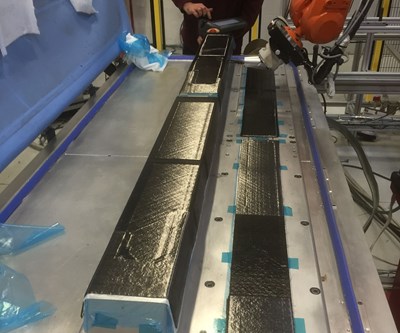

Automation options arise for labor-intensive composites

Typically labor-intensive fabrication processes have more automation options as new technology works in concert with operators to improve efficiency.

-

CAMX 2019 exhibit preview: Aligned Vision

Aligned Vision is featuring its recently launched TARGETGUIDE automatic alignment system at CAMX 2019.

-

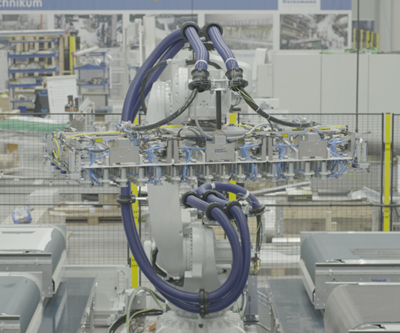

Evolving AFP for the next generation

‘Aerospace quality at automotive pace’ is the mantra of the supply chain being developed for next-generation commercial aircraft. Automation is evolving to meet the challenge.

-

Automated, in-situ inspection a necessity for next-gen aerospace

Inline inspection technologies continue to evolve with the aim of providing faster and more accurate part inspection.

-

Plant tour: Spirit AeroSystems, Wichita, KS

Spirit AeroSystems was an established aerospace supplier when it earned that distinction, winning the contract for the Boeing 787’s Section 41. Now its sights are set on the next generation of aircraft.

-

Plant tour: Elbit Systems Ltd., Haifa, Israel

Military and commercial tier supplier Elbit Cyclone maintains precision and quality as it continues growth in composites, complex assemblies and high-rate production.

-

Plant tour: Kanfit Ltd., Migdal HaEmek, Israel

Aerospace tier supplier Kanfit Ltd. is expanding, offering both composite and metal parts for applications in an expanding range of high-performance markets.

-

Composites at AeroDef 2018

Highlights from the Aerospace Defense Manufacturing Conference – AeroDef 2018 include new technologies for tooling, drilling/machining and inspection of advanced composites.

-

McNair Aerospace Center: Closing the composites education gap

As the composites industry in South Carolina continues to expand through Boeing and its tier suppliers, composites education follows suit through the McNair Center.

-

Improving composites processing with automated inspection

Automated, in-situ inspection bypasses the bottleneck of manual inspection.

-

Machine vision: Rapid error detection

Aerospace-aimed ply placement technology evolves into process management and near-real time inspection system for production laminated composite parts.

-

Laser projection: Envisioning more than templates

Advanced systems offer ply-placement verification, aids to faster assembly and manufacturing process and quality control.

-

CAMX 2014 exhibit previews, part 2

With CAMX 2014 less than a week away (Oct. 13-16, Orlando, Fla.), ÂÌñÏ×ÆÞ offers a final glimpse of some of the products, technologies and services that you will find in booths in the Exhibit Hall. During the show, we'll keep you informed and up-to-date with the CAMX Show Daily, which will be distributed Tuesday, Wednesday and Thursday at the show. Safe travels to Orlando and we look forward to seeing you at the conference and trade show.

-

SAMPE 2013 Long Beach new product showcase

The SAMPE 2013 trade show (May 6-9, in Long Beach, Calif.) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the HPC editorial staff's compilation of what was on display.

-

Ply placement: Largest laser projection system for wind blade manufacture

Following the recent installation of a 16-projector system for an aircraft fuselage application, Assembly Guidance Systems Inc. (Chelmsford, Mass.) recently delivered what it says is the largest unified laser-projection system of its kind, for wind turbine blade fabrication.

-

JEC Paris 2011 Review

This annual Paris trade event’s statistics signal an advanced composites resurgence.

-

JEC Paris 2011 highlights

The news from this annual Parisian in-gathering of composites professionals is heavily weighted toward automotive lightweighting.

-

The Private Space Race

NASA passes the development torch to legacy contractors and NewSpace entrepreneurs, igniting a new competition in space transport.

-

Formula 1 team accelerates design-to-track speed

Race car builder automates manual chassis design phase with unique FEA-to-CAD utility.

-

Update: Automated repair cell

Consortium makes progress on aircraft component diagnostics/repair cell concept.

-

Sky's The Limit For Composites-intensive UAVs

Market growth is being spurred primarily by post-9/11 combat actions, homeland security and natural disasters.

-

Automated Aircraft Repair Closer To Reality

Inspection and Repair Preparation Cell (IRPC) unveiled, revealing progress made toward automated aircraft repair workcells.

-

SAMPE 2005 Product Showcase

SAMPE's U.S. Symposium and Exhibition highlights technological innovation and market expansion.

-

The craft of aircraft repair

As the use of composites on commercial and military aircraft grows, repair facilities seek more science in what remains a primarily manual art.

-

Composites take off ... in some civil helicopters

Slowed by certification requirements, composites nevertheless are finding their way into the fuselages and rotor blades of commercial helicopters.

-

Post-show review of the 2004 U.S. SAMPE Symposium

Largest-ever Symposium serves up a large helping of news and new technologies from advanced composites suppliers.

-

Laser projection systems improve composite ply placement

Lighter, more intelligent and increasingly versatile laser systems light the way to accurate and efficient ply placement.