Search Results

Showing 21 – 30 of 780 results

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

Bonding and welding play vital roles in the assembly and fabrication of composite materials, offering methods to join components together effectively. Bonding involves the use of adhesives or bonding agents to create strong connections between different composite parts or between composites and other materials. Adhesives provide uniform stress distribution, enabling lightweight and durable structures. On the other hand, welding techniques like ultrasonic welding or induction welding are employed specifically in thermoplastic composites, where heat is used to melt and fuse the materials together.

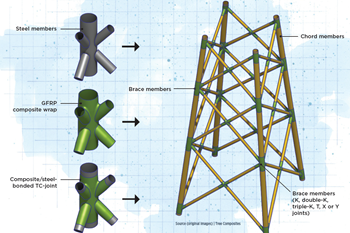

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Thermoplastic composite upper and lower half shells for the Multifunctional Fuselage Demonstrator were welded using CO2 laser over a total length of 8 meters.

The agreement will focus on infrared welding technology to enable high-volume, automated manufacturing in aviation.

Project optimized design and production of UD composite tapes reinforced with a PEKK matrix, using a continuous in-situ welding (ISW) assembly system.

Longtime parts manufacturer offers more than composites welding. CW’s conversation with CEO Kjelt van Rijswijk explains KVE’s vision with Daher and where it’s headed.

Clean Sky 2 HELACS project aims to enable improved recycling of composite components at aircraft end of life.

To meet sustainability targets and market demands, the aerospace industry is searching for alternative joining methods. Automated assembly of thermoplastic composite structures by induction welding offers a solution. (Sponsored)

Flexible welding cell developed for coupon welding to facilitate process qualification of KVE INDUCT welding technology for thermoplastic composites.

Modular GFRP W-tanks fabricated by Toro Equipment simplify the logistics, space and time limitations involved in anaerobic digestive and water treatment containers.

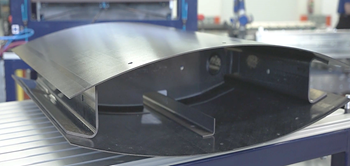

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.